The Radio Detective is back!

A VTVM is what? Vacuum Tube Volt Meter.

“But George, you idiot, I don’t HAVE a VTVM!”

Totally get that. But you see, it’s a nice, simple, way to dabble your toes into things electronic. Thing of this as two weekends of “easy learning” a few things about how electronics work, break, and how to fix it.

A VTVM is just about the simplest piece of gear on the shelf in the lab. A power supply, a tube or two (or a field effect transistor in newer units). A big easy to read meter.

This is the kind of Project we do when the new air conditioner has the Office nice and cool and it’s hot as hell outside. We’ll do the generator shed and the new deck projects in a couple of weeks (future columns) when the weather lets off the Heat. I have probably bored you with the other indoor hobbies like CNC and 3D printing. You might get a kick out of model-building, but a 40-inch-long sailing ship is a hell of a lot more than a single column’s work.

Weather’s is to blame (along with some of my natural laziness!). Working (I mean really turning to…) is not nearly as productive north of 80F outside. Above that is past my personal cut-off temperature. I believe in staying frosty.

Electronics indoors season has been fun: 2 weeks back, we did the overdose on SDR radios, and last week the Redneck Cooler, all in keeping with being “under air” till Hell shuts its open door in the South for the year. October first, maybe.

So, About VTVMs Then…

It is the electrical instrument that got us (America including electronics and computer outfits) through the growth spurt in the 1940s, 1950s, and well into the 2000s. They only measure only a handful of electrical parameters. But they do it extremely well.

- They measure AC Voltage (in Volts of Alternating Current)

- They measure DC Voltage (in Volts of Direct Current)

- Then they measure Resistance (in Ohms)

To make volts, amps, and ohms reasonably comfortable to sort out, let me use my “Water Analogy.”

- Volts is electronics’ analogy to “water pressure.”

- Amps is the analogy to “water flow rate” (*as in gallons or liters per minute, right?)

- Ohms are like the “friction losses” in the pipe.

Badda-bing! You just became an electronics technician!

Test Equipment is where you find “technical gourmets. They bandy about names like Tektronics, Fluke, Rhode & Schwarz, along with a host of others.

Somewhere, you may have run into, or seen, a classic Volt-Ohm Meter (VOM) like the old-fashioned Simpson and Tripplet meters, or the semi-clone from China I picked up last November. $39 and change. These old-school analog meters usually also measure Current (in amperes) which most VTVMs do not.

The break point between using a VTVM or a VOM usually the amount of “circuit loading” the measurement induces. The big bullet proof Volt-Ohm-Meters are great for general shop work. Especially for the simple stuff: How many volts at that electrical outlet? Or, is this a good battery or not? Maybe even “How small a wire can I get away with at this current flow?”

But, if for example, if you want to measure a very small voltages AND in very sensitive equipment? You just crossed over into VTVM territory.

The VTVM doesn’t put much “load” on a circuit when measuring. Up in some cases more than a million Ohms of resistance for each volt. Those VOM’s make good measurements, but those meters can load-down the circuit under test. In really touchy situations and close tolerances they can screw up any chance of a super-accurate reading.

We will get into specifics of how a VTVM operates in a minute. But, let’s also look at the digital multimeters. DMMs. These use very sensitive and accurate electronics to measure (using software) things including voltage, current, resistance PLUS frequency, capacitance in Farads and even inductance (coil properties) in Henries.

My normal bench tool is a current generation Owon DMM on the bench.

For today’s report aimed at an electronics orientation class, I grabbed an aging VTVM that I’d picked up – and noticing it wasn’t working right. It’s been sitting on the “I’ll get to it” shelf for, um, since before we bought our airplane. 2012 maybe?

My object is to fix it up and (maybe) move it out.

How Electronics Break

Fortunately for process-map driven, compressed-learning, sigma males (like me or G2) Electronics fail in reasonably predictable ways. Let’s go through the major suspects behind many electrical equipment failures:

- Mechanical Breakage: If you turn a switch on and off, 100,000 times, you are likely to get a failure. (*stuff wears out).

- Wires Break. Ditto if you twist a cord often enough, metal fatigue in the wiring will cause problems. This is why during WW2, the military was very particular about using stranded wire rather than (easier to work) solid wire. Solid didn’t hold us as well in high vibration settings. Aircraft, tanks, and what have you. (Many people don’t appreciate all the learning we came into modernity learning the hard way on the way up.)

- Dials and Knobs Wear Out: Most of the knobs on equipment go to either a switch (we just mentioned they fail) or variable resistor. Others go to capacitors (for tuning some circuit or other) while the dials and other indicators fail with extended use, as well. Not such a big deal NOW, but if you took a radio course in the late 1930s, there would be plenty of teaching passed on about how to “restring dial cords” and whatnot.

- Dirty variable resistors cause old radio volume controls to sound “scratchy.” Called potentiometers, the knob fronts for a flat carbon arc resistor with connectors on each end. Sliding along this is a small metal wiper that makes contact in different places inside the “pot.” Changes resistance this way, or that. When a “pot” is dirty (carbon oxidizes over decades of use) a film will build up (along with dust and such) causing the wiper not to make regular contact. This is how “scratchy volume controls” arrived from long ago.

- Tubes Wore Out: Old school. This is mainly a circumstance of either a seal leak around the pins of a vacuum tube, too much mechanical shock, or simply wearing out from too many hours on them. In modern (solid-state) components, you don’t see nearly as many failures. Mostly, when they occur it is from a static spike or it’s from another component failing. Still, I’ve seen early 2000s integrated circuits fail for no reason apparent to me. But this is easily sorted out most of the time.

- The BIGGEST problem is aging tube type equipment is Capacitors. A capacitor is two metal plates and they “hold an electrical charge.” But not for weeks or months like a battery (which also has plates). Most capacitors are only required to hold a charge for a little while. In some cases, a few millionths of a minute.

- BIG SAFETY WARNING HERE: Big capacitors of very high quality WILL hold significant energy over time. Like that one on the our heat pump that buggered out this week. Enough energy is left in large capacitors to KILL YOU. The way to avoid this is? Always disconnect anything you’re tinkering with from mains (AC) power. Then use a screwdriver to absolute ensure the power filtering capacitors in all high voltage circuit have been shorted cross. I remember being in a hurry to short out the power supply “caps” on a Collins 21E broadcast transmitter. It zapped nearly an eighth of an inch off my favorite screwdriver! Sounded about like a 22. (short) round going off.

- Never work with leather shoes on. Leakage to ground is possible. If in a chair, plastic casters and dry mat. KEEP ONE HAND IN YOUR POCKET so as to never risk an accidental circuit completion across your chest. If you are not dead certain get some lineman gloves, too. Must be present to live. Find someone local to coach you.

- There are other failures, but much less frequent. This includes resistor values changing over time (they do!) and also coils managing to open up (even rarer, short).

About here, you may come to realize that fixing any piece of electronics comes down to going through an organized repair process.

I showed you the view of my electronics workstation last week. This is where I fix things and tinker. (Time machine is in the other building.)

Like working on a car, the best mechanics seem to never get their hands dirty. Same thing in electronics. Clean as you go and there’s a lot more satisfaction when something is placed back in first-class working order.

Electronics Troubleshooting Process

- The first step is to get the piece of equipment.

Do you want it to work? Do you want to resell it in restored condition or at least “tested this far” condition? Like an Actor, you always do a “first read” of a piece of gear while asking “What’s My Motivation, here?”

Depends on your time, knowledge, and understanding who will buy a “pig in a poke” online.

I could likely sell this unit on eBay, as it sits. $50-$60 bucks? People will buy damn near anything these days including woke speak and Biden’s spiels, lol. Simple fact is similar units in good working order can go for well over $100. Could I use another $50 above the pig-in-poke “tested to power on only”? You betcha. Besides, it’s more fun than daytime TV on a hot day. Gets the old noggin joggin.

Second is the Visual Inspection.

Three arrows to be aware of – and we’ll cover these top-to-bottom.

The top white arrow: points at a screw on the front panel. It doesn’t seem to have been moved in years. To an old radio repairman this may be a flag when troubleshooting for this reason: The chassis of older electronics acts as the power supply negative return path. If the ground screws in this unit have corroded much, they can build up resistance and that will usually degrade performance. The little bit of rust is a hint at maybe ground problems lurk.

The Middle white arrow: points at a power indicator. This is a small neon light that is supposed to come on when the unit is powered up. This may seem like a really tiny nit. But, when you have used electronics tools for a living, you get to be fairly (to extremely) particular. You don’t turn out crappy work, do you?

The fact that the light is there means it better work when I’m done. We don’t know yet if it works, yet, though. Since notice we have not gotten to plug in and test yet. We’re still in “size-up” mode.

Also, on either side of this are two adjusting potentiometers. They turn and they have wipers, so we can plan on several things already. In addition to the neon light check and a good cleaning, we’ve added Fader (Lube) F5 from the same folks who make DeOxIt. The Fader Lube seems to last longer when you’re not using equipment as often. Not as aggressive as DeOxIt – depends on the and mood of the tech.

The Bottom Arrow: gives us the manufacturer’s name (HeathKit) and the model number. With this information jotted down, or memorized (VTVM Model IM-13), we go on to the next step in our process:

Third Step: Get the Manual

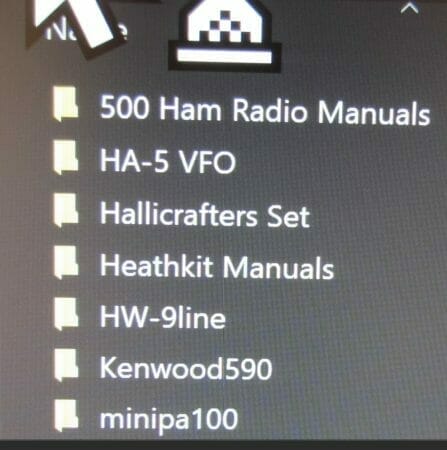

If you have any equipment (electronic or otherwise), it’s not unreasonable to have an old computer with a big-ass hard drive on which you can store a collection of manuals for everything in your inventory. As you would find, looking over my shoulder on the electronics bench computer, I have manuals I’ve collected over the years for almost everything in the inventory here.

Literally, I have an ungodly number of manuals. Some of them come from the highly prized Boat Anchor Manual Archive (BAMA). Others were whole catalogs of collected manuals. I likely have manuals on most HeathKit ever built and ditto Hallicrafters equipment, which is my favorite of all old-school gear to collect and work on. https://mods.dk is great, too. Oh, those clever Danes, huh?

You can also find manual collections on DVD or thumb drive on eBay for under $50 bucks. I just ordered the manuals for Yaesu ham equipment of a certain vintage from this guy. Since I have a non-op Yaesu FRG-7, the owners manual and schematic diagram will be worth every big of $17 bucks.

4th: Read the Manual and Understand the Equipment

Sitting at the electronics bench computer, I opened up the manual for this HeathKit VTVM. I already had a pretty good idea of what I’d be finding. But I always look at the schematic before opening in order to get myself oriented to what goes on inside the box.

What is a Schematic?

A circuit diagram is a schematic. Schematics are based on standard symbols. A tiny resistor (half the size of a grain of rice for in SMT boards) is the same symbol in a schematic as a HUGE power resistor that’s 6-inches long. Part of learning electronics is (over time) figuring out the corresponding parts between a diagram and the physical actuality of the equipment.

I figured inside this VTVM there would be a small high voltage power supply. This is where we start to translate schematic diagram representations to visual expectations.

Capacitors with a flat plate and a curved one are generally flat is the (+) connection. The curved part goes to the (-) connection. Capacitors with parallel plate (that are straight) are called nonpolarized and it doesn’t matter which way you put them in. Both ways work.

This is a very common (low current, high voltage) power supply. But since we know that capacitors (ESPECIALLY electrolytic power suppl filter caps) dry out and lose their capacitance over time, we MIGHT want to measure that capacitor when we get the unit opened up.

4(b): Basic VIVM Innards

The next part of the circuit flows from left to right, generally. By convention, good schematic practice (when I am not scribbling on a yellow pad) is to go from the Antenna (or inputs in this case) on the Left of the schematic. Then have the speaker on the Right side of the schematic for a Radio. For a VTVM we would find that big analog meter off on the right somewhere.

How does it work? Well, if you arrange four components in a diamond shape you have something called a bridge. When one side of the bridge changes, the bridge becomes unbalanced. Now, let’s assume we were measuring a 9-volt battery.

The wiring on the left (switches to scale the voltage to the tube correctly) changes the very small current flowing through the dual-diode tube, a 6AL5. From 60 decades of soldering, we remember this is a small 7-pin tube.

Not shown is the small battery – which drives the precision for the 6AL5 portion of things. This is almost certainly dead. We seem to remember when my buddy The Major built HIS HeathKit VTVM in 1966, that it had a 1.5-volt D battery, though it may have been a C cell. *((Aging is a bitch when you can remember a battery size for sure and certain after 57-years!))

When the 6Al5 voltage is unbalanced the bias (a small voltage controlling a larger one) changes on the 12AU7 (medium gain dual triode with the other pint for heater power).

Simple, not terribly intimidating.

Now, we can do what?

5. Initial Function Testing & Work Plan

The great turn-on debate must be settled. Many techs working on older equipment argue that they should all be started up slowly using a special variable power transformer (called a Variac if you care). The story is this will give capacitors a chance to re-form to handle rated voltages. Instead of going right to 120 VAC, these cowards (afraid of the possible smoke and maybe the odd flame flash or two from blowing up capacitors) insist the time is worth the effort.

My personal experience is if something is going to blow, might as well do it right now, and get on to fixing it. My thinking in marginal equipment that has to be treated this gently has issues that should be fixed right away, rather than be put in service and maybe failing when really needed.

This argument has been going on over the ham bands for at least 70 years, that I can attest to.

We’ll just turn the damn thing on. We’re well stocked in fuses, too…

The Get Ready for this is to get some things (from the junque drawer) to measure. Assuming the VTVM works. Since it is supposed to measure Resistance? Three resistors should work. One low value, somewhere in the 33K to 100K range, and one up in the megohm range. For voltage sources, a nine-volt battery and a couple of triple A batteries will work. For measuring AC, we might plug the probe into a wall socket, though I don’t try that kind of (wild-eyed shit) until the resistors read correctly and the batteries read right.

The “B” part of this is to make a table of what works and what doesn’t.

Then (if some things work, others don’t) we can already see how we’ll be able to narrow in on the trouble source.

We’ll go through the workplan in a future episode of The Radio Detective, but for now, we will “enter the equipment” knowing to expect:

- We will have a list of squawks from the functional test.

- Tightening of grounds.

- Replace the (likely) dried up capacitor in the power supply.

- Change the reference battery.

- Test the 6AL5 and the 12AU7 tubes and note strength or replace as needed.+.

- FaderLube all the pots and the switches, drop of gun oil on the switc h shafts.

- Confirm function of the neon power indicator light.

- And measure the resistance of the test leads.

- Last part would be to open up the HeathKit assembly manual and confirm the calibration of the unit.

Finally, we will then turn on the gear, do another functional test. If it passes, a tag will be prepared and it will go into the sell on eBay pile, OR we will get back inside the unit to look for a specific problem that failed in functional testing.

As should be clear, I spend a bit of time on the front-end of restoring to operation. It’s part of the fun, don’t you know?

In the next episode, we will do the Work Plan with a few pictures and enjoy the hell out of bench time.

Oh, yes, did I ever mention how much technical documentation I’ve written over the decades? Makes my head spin just thinking about it! Mounds and piles, whole catalogs worth. Which is why Urban is so easy to write…

Write when you get rich (or peace breaks out),

George@Ure.net

“From 60 decades of soldering, we remember this is a small 7-pin tube.”

Wow! You’re WAY older than I thought!

My next odo reading is 75 – and I’m already there if counting womb time, lol.

Yep started soldering at 12, first Weller soldering gun at 13.

74 is not old, but it’s not so young, either.

Uh, 60 decades makes you over 600 years old.

Mmm…seems like a runaway decimal point.

Somebody is stealing decimal points again, from your reference to the *63* volt filament winding! That would make the tubes into flashbulbs!

I like the idea of forming the capacitors first. Not because of the drama, but the cost.

Why buy and replace stuff when you don’t even know what other problems exist? I’d get it working well enough and then think about recapping, but that’s just me.

There’s a reason (we pilots) are crazy mf’ers when comes to preventative maintenance. Losing an engine in flight really, really is a problem!

OK, losing a receiver in the middle of the CQ Worldwide phone contest on 20-meters may not be as critical. But if the caps are old and unused enough to need reforming, my default is fix in advance at my convenience.

Just me and YMMV

George…..thanks to you I finally grasped what volts, amps and ohms means!!! I used to work construction , Operating Engineers, Local 18, and we did water mains. NOW I get it! Lol. Geez…..almost 70 yrs old and finally figured it out! Well Done SIR!

Every day in every way, we keep getting smarter and smarter. Hopefully!

R U experienced?

…sub tender, welded to pier – TAD ..electronics shop (IC repair)

– You will catch a cap thrown in Ure general direction..just once, in Ure lifetime.

Now, correctly assume all of em “charged” – full potential ; ) fkrs.

“catch a cap” LOL

Worked in a tv repair shop during jr college; it was owned by two ex-navy ETs. Lots of good learning but also lots of ‘surprises’. And not to be forgotten was ‘fun with circuit chiller’…

JD, freeze mist was only fun until it got expensive.

I never “caught the cap.” I’d smack it with my wide open hand and send it back from whence it came. A brother and a next-door neighbor were both ETs. I learnt all that stuff while I was still too young for them to pick on…

Catching the cap is nothing compared to touching the HV terminal of an old CRT picture tube… even if it had been dead for weeks. Damn things could soak up enough atmospheric charge to draw a spark anytime.

@Hank

“Catching the cap is nothing compared to touching the HV terminal of an old CRT picture tube…”

Yeah, did that too — without any brotherly love involved — fixing my folks’ Zenith B&W. THEN because I was young and stupid, did it again a couple years later with a Silverstone color TV.

For those who never: The high voltage box in a black & white TV put out about 18,000 volts. The HV box in a color TV put out above 30,000 volts. Keeping that hand behind you is REALLY IMPORTANT!!!

Ok.. I just have to share this.. I tried something new.. it was baked snap pea’s or dehydrated snap pea chips.. boy was it good.. they were like potato chips but way better..

if you have a freeze dryer that’s the way to go.. snappy crunchy..I am thinking about soaking them in salt water like you do with peanuts or sunflower seeds..just to try it..

Ingredients

Ingredients:

Fresh or Frozen snap peas

sea salt

onion or garlic powder

nutritional yeast

?

Instructions

Ingredients:

Fresh or Frozen snap peas

sea salt

onion or garlic powder

nutritional yeast

Directions:

Lay your snap peas on a paper towel or parchment paper. Season with sea salt, onion powder, and nutritional yeast. Dehydrate in dehydrator at 135-140F for 8hrs or so. Let them sit another hour at room temp before packaging. If you are using fresh vs frozen snap peas, the dehydrating time will be faster, so check around 6 hrs.

Don’t have a dehydrator? Just use a toaster over or real oven. Set your temp at 170F and prop the door open about 1 inch. You can use a piece of foil do that. The cooking time will be shorter, so check around 4 hrs.

Season more once dried if desired.

Five modest shop enhancements I’d suggest:

1) Sufficient “on-stage workspace.” Most of us build a diagnostic suite of breadth, but then allow too little actual “patient space” to actually work on The Beast.

2) A shelf-liner “rubber mat” for the work stage. Prevents slipping, and won’t scratch old paint and cabinetry.

3) A turntable sufficient to carry maybe 50 pounds for bigger boatanchors. Mount to two thin-ish wood squares for stability and instant removal when not tneeded. (“Hardware store grade,” not some flimsy plastic pantry spice rack cheap-ass $8.95 piece of Krappe.)

4) A proper solder-station with rack and sponge tray.

No need to go crazy – just basic is good enough and important.

5) A decent “AC Line Voltage” monitor meter. You need to know when the AC is brown in summer.

Damn-fine comments WmoRR. Some answers:

1. whole black table on the left is sometimes empty when starting on a new project.

2. It is 48×23 and comes with a pvc clear table cover. On this goes a silicon workspace – the small 18X13 kind with the little parts trays. But I really prefer a totally flat surface so that will be changing.

3. I tried a turntable on the general shop bench but found it was more bothersome than anything. This may be a reflection on me – I’m a screw dropper and every small part was magically drawn under thgis 14″ round thingy I tried. What seems to work best is having for boat anchor receivers, tilting them up pon their sides – the side with the power supply. Usually heavier and at least in most of the old gear, tradition has the RF front end on the far side of things. Again, great reminder, though.

4. There are two soldering stations. A combo hot air smt and sharp pointed regular made by Yihua, and a single with wet solder pad which is also temp controlled. I like results with the rosin-soaked brillo pad looking tip cleaners best,, but the liquid flux with a tiny metal needle is he best – even better of NoCrode flux

5. I’ve considered this, but we don’t get brownouts here. On reason is if I am selling power to the grid. If they get below my sell threshold their demand could (in theory) go up… I hav e one of those kill-a-watt meters though because I don’t trust the power company any more than I trust the CIA,,,

Regarding the line voltage monitor, I’ve a preference for watching both legs of the split phase 220! The most insidious and dangerous line condition(besides lightning) is a floating neutral. Depending on load per leg, one phase can go anywhere from a few volts to perhaps 200V. I had this happen with an oxidized neutral connector at the service entrance. It’s obvious at a glance with two large meters. The grounded neutral at both the pole and main box should prevent this(in theory), but it’s not the way to bet, and, of course, a ground path should not be carrying current.

I could never convince my wife’s granddad that you need a 3rd wire ground circuit, mainly because so many appliances in his generation didn’t have one. Since the ground and the common wire both go back to grounded bus bars in the electrical box it simply didn’t make sense to have an extra if only for cost alone.

One time I found a dead short in the wiring we were putting in when building the back side addition to our house, a project he insisted on, because there was zero resistance between the hot and common wires. As I was trying to trace it down I wound up pulling an entire section of wire out of the wall, this was before sheet rocking the place, and it ticked him off so much when he found out about it he quit talking to me pretty much until the day he died. It turned out at the very end of the circuit (I ran out of time with that trouble shoot so I never got to the end) the hot wire’s insulation had been cut through by the single gang electrical box’s sharp edge on its penetration point and a dead short resulted. He also didn’t believe in putting the strain relief clamps on those boxes which directly resulted in this condition. It was part of his Depression Era thinking of cutting as many corners to save a penny or dime here and there. It never occurred to him doing it right the first time is better than burning down the house or electrocuting his favorite grandson who was going to move into that room.

He was a truly lovable character but his thinking became solidly ossified the last 5 or 6 years of his life. I’m beginning to understand him more and more now that I’m getting into that time in mine.

One thing about boatanchor radios is they have a 2-wire plug, where both prongs are the same size, and the radio chassis is often the ground for the entire radio.

Stop and think about that for a second…

This means, you’d have a 50-50 chance, every time you plugged it in, of making the chassishot! Picture this: Radio on kitchen counter, you’re washing dishes or drawing water, you reach over and adjust the radio. If the chassis is hot and the case or knob is metal, you just stuck your hand in an outlet…

Another excellent treatise as usual. With the exception of kinetic activities where everything can go anywhere at anytime following the process, aka recipe will be successful most everytime.

Like you mentioned, I also have 3 ancient desktops and a couple laptops holding tons of manuals, instruction sheets, MSDS for just about anything and wait there’s MORE. I picked up a 4Tb network drive a while back with the intention of getting all that stuff off the decrepit old machines before the hard drives fail, one being a windows 98 machine. I’ve reached out to a couple network engineers and IT types from the office to see if they could offer assistance with the data transfer and setting up some sort of a searchable database.

Wife says I am overthinking it but when I said several gigs are photos and videos of the kids she said, Oh….. never mind.

Hunters business partner testifies thie week. Get ready for

a major announcement about UFO’s

Stay safe, 73

the DOJ wants Archer to report to jail now, before testifying before congress on Monday,,, they are ducking scared, duck duck duck,

https://twitter.com/ChuckCallesto/status/1685670381519015936

yup, some UFO stuff to keep the sheeples’ attention,,, got to create chaos, to keep attention away from the real crimes and criminals, Bribem crime family is just a small part of the overall global crime syndicate ran by PEDOs and they own the DOJ and they are incorporated,

Whore of Babylon

What do you want to bet.. if be reports to jail.. he will mysteriously commit arkincide.. oh I mean suicide.. the disease of the beast.. hunter will walk..

either way hunter will never see prison time..

if he survives going to jail he will never talk again..

check out Juliana fate..he exposed so much all of it gone and he will never see the light of day as a free man.. if he is sent to the usa he to will commit suicide….

its their way…. dual standards cards of law

You’re taking me back to the last time I worked on tube-based equipment (a Navy Talos missile tracking radar in the early 60s). Thanks for the memories.

Why would this story not be reported as headline news in every major media outlet?

https://www.zerohedge.com/geopolitical/ive-never-seen-anything-mysterious-chinese-bio-lab-discovered-remote-california-city

Because the media is controlled, maybe?

gee G… what gives you that idea..

https://hotair.com/headlines/2023/07/28/hunter-plea-deal-judge-tells-prosecutor-you-can-sit-down-n567668

https://twitchy.com/samj/2023/07/30/devon-archer-n2385847

https://redstate.com/sister-toldjah/2023/07/28/watch-underreported-press-briefing-moment-on-bidens-whereabouts-raises-more-questions-on-the-hunter-issue-n783976

now my thoughts on the bottom article..and about how the Biden family refuses to acknowledge or get to know their seventh grand daughter.. seriously.. I mean seriously..all the alleged crimes and the alleged paedophilia and incest..the abuse of power and family.. now would you want them to have any contact with her at all.. not a chance in hell..keep the little girl innocent and let her grow up being lo ed and cared for and not subjected to that evil family..I personally don’t think any of them should be allowed within a mile of any parks or school grounds..

https://redstate.com/sister-toldjah/2023/07/30/watch-hurt-feelings-erupt-after-scott-jennings-reminds-cnn-panel-who-hunter-biden-really-is-n784881

loob, if you know so much about Biden’s personal life, you should be reporting the details to the authorities, instead of running amok with misinformation,

Redstate; low reliability, hyper partisan:

https://adfontesmedia.com/redstate-bias-and-reliability/

Muncie, Indiana (Ball State University) is a regular stop on my foraging. Yesterday there was a mass-shooting: 1 dead, 19 sent to the hospital with gunshot wounds and several of those, later airlifted, probably to Indy.

It will get a mere mention in any news media, and in two days, be gone from the news cycle forever, because it was Black on Black crime.

News items which support the narrative of the communists in the Western “press” or Western governments get air time for weeks or months — sometimes even accompanied by 500-some riots.

News items which don’t support said narrative get as little mention as possible, and get buried as soon as, and with as little fanfare as is possible. Sometimes they get mis-reported in print, in large type, on Page-1, with retractions or corrections entered in 6-point type, several days later and in the lower right corner of the obituary or entertainment page.

A communist Chinese lab in SoCal does not support any “mainstream” “news” narrative…

Good info on mower recoil.

https://www.youtube.com/watch?v=BS-5j7-XE8Q

For Dried Corn Starch:

Ingredients:

Fresh corn kernels

Instructions:

Start by shucking the corn and removing the husks and silk.

Cut the kernels off the cob using a sharp knife. Try to cut as close to the cob as possible to get the most corn.

Spread the corn kernels evenly on a baking sheet lined with parchment paper or a silicone baking mat.

Place the baking sheet in an oven set to the lowest temperature (around 140-150°C or 275-300°F). You want to dry the corn without cooking it.

Leave the oven door slightly ajar to allow moisture to escape. This helps prevent the corn from steaming rather than drying.

Check the corn kernels regularly and stir them to ensure even drying. The drying process may take several hours, depending on your oven and the moisture content of the corn.

Once the corn kernels are completely dry and hard, remove them from the oven and let them cool.

Grind the dried corn kernels in a food processor or coffee grinder until you get a fine powder. This powder is your homemade corn starch.

For Dried Potato Starch:

Ingredients:

Raw potatoes

Instructions:

Wash and peel the raw potatoes.

Grate the potatoes using a fine grater or the fine shredding blade of a food processor.

Place the grated potatoes on a clean kitchen towel or cheesecloth. Wrap the towel around the grated potatoes and squeeze firmly to remove as much liquid as possible.

Spread the squeezed potato pulp on a baking sheet lined with parchment paper or a silicone baking mat.

Place the baking sheet in an oven set to the lowest temperature (around 140-150°C or 275-300°F). As with the corn starch, leave the oven door slightly ajar to allow moisture to escape.

Check the potatoes regularly and stir them to ensure even drying. The drying process may take several hours.

Once the potato pulp is completely dry and hard, remove it from the oven and let it cool.

Grind the dried potato pulp in a food processor or coffee grinder until you get a fine powder. This powder is your homemade potato starch.

Store your homemade corn or potato starch in an airtight container in a cool, dry place. When you need to use it as a thickening agent for gravy or other dishes, simply mix it with a small amount of cold water to form a slurry before adding it to the hot liquid you want to thicken. Stir well to avoid lumps, and cook until the desired consistency is achieved.

Keep in mind that homemade starch may have slightly different properties than commercial starch, but it should work well for thickening your gravy and other sauces.

you can use your freeze dryer or dehydrator to.. its way easier.. then blend up the dried starch to a powder..

https://youtu.be/wTp3_WlyNxs

that’s a good video of it.. now if you dry the corn you can grind it into a four crumble it into chunks for the birds etc.

the same with the potatoes..

cotton candy floss sugar..

1 cup of sugar

A few drops of flavoring or a packet of koolaid and a couple drops of food coloring.. out in your ninja blender and mix well..almost to a powdered sugar consistency.. let sit over night..then blend again..

1 tbsp. per cotton candy cone

Simple solder station:

https://www.amazon.com/Weller-Digital-Soldering-Station-WLC100/dp/B000AS28UC/ref=sr_1_33_sspa?keywords=soldering+station&qid=1690732233&s=industrial&sr=1-33-spons&sp_csd=d2lkZ2V0TmFtZT1zcF9idGY&psc=1

Others of this level of (non)complexity are around at lower price points. (Rarely is it that three significant digits of tip temperature accuracy is needed.) And 40 watts is enough for basic-basic work. Surface mount stuff and DE-soldering “re-work” stations make for a lot of hardly-used complexity. For heavier work, get a Weller “GUN” at the 150 watt level.) (PL-259s & grounding lugs)

Handy shoptip: Scan your 2x4s for a large, sappy knot. Cut out about a five-inch long chunk containing the knot. Using a ball-peen hammer, make a shallow DENT in the center of the sappy knot. Now, appply your soldering tip directly to the center of the knot, in your little shallow depression, and feed about two or three inches of solder from your roll, melting it into a nice blob of liquid solder “dip-tinning pot” of about the size of three stacked dimes. This can be re-heated anytime to make a mini-“solder pot” thermal stripper for magnet wire with enamel coating, AND it can be used to immerse and clean your soldering tip in a cleaning-wiping cycle. Always remember (and never forget) a CLEAN tip is a HAPPY tip!

That’s twice today you had me laughing my ass off.

First with the “Hardware store grade,” not some flimsy plastic pantry spice rack cheap-ass $8.95 piece of Krappe.

And now with “a CLEAN tip is a HAPPY tip.”

Thanks for the laughs.

Like the video says don’t cut the kernels off.. I get dried shucked corn .. most stores sell it for birds.

it is a similar process with making sugar.. with making sugar here’s the recipe.

https://youtu.be/UGGWTnHgm1c

you’re interested in the basic process of extracting sugar from beets, here’s an overview:

Ingredients and Equipment:

Fresh sugar beets

Food processor or grater

Large pot

Water

Cheesecloth or muslin cloth

Sugar thermometer

Clean bottles or containers for storage

Instructions:

Prepare the Beets: Wash the sugar beets thoroughly to remove any dirt and debris. Peel the beets using a vegetable peeler or a knife. The skin of the beets is bitter and not suitable for sugar extraction.

Grate or Process the Beets: Using a food processor or a grater, grate the peeled beets into small pieces. The finer the beet pieces, the easier it will be to extract the sugar.

Extract Sugar Juice: In a large pot, add the grated beets and cover them with water. The exact water-to-beet ratio isn’t critical, but enough water to cover the beets will suffice. Bring the mixture to a boil, then reduce the heat to a simmer. Cook the beets until they become soft and release their juices.

Strain the Juice: Once the beets are cooked, strain the mixture through a cheesecloth or muslin cloth to separate the beet juice from the solid pulp. Squeeze the cloth to extract as much liquid as possible.

Clarify the Juice: The extracted beet juice will likely be cloudy and contain impurities. To clarify it, heat the juice to around 70°C (158°F) and let it sit for a while to allow the impurities to settle at the bottom. Carefully pour off the clear juice from the top, leaving the sediment behind.

Evaporate the Juice: Transfer the clarified beet juice to a clean pot and heat it gently. As the liquid heats up, water will evaporate, and the sugar concentration will increase. Use a sugar thermometer to monitor the temperature. The goal is to reach the point where sugar crystals begin to form, but without burning the syrup.

Crystallize the Sugar: Once the sugar concentration is sufficient, remove the pot from heat and let the syrup cool slightly. As it cools, sugar crystals should begin to form. Stir the mixture gently to encourage sugar crystal growth.

Separate Sugar Crystals: Once the sugar crystals have formed, carefully pour off any remaining liquid, which is now a sugar syrup. Separate the sugar crystals from the remaining syrup, and let the crystals dry on a clean surface.

Store the Sugar: Once the sugar crystals have dried completely, transfer them to clean bottles or containers for storage.

Keep in mind that making sugar from beets at home is a time-consuming and labor-intensive process. Additionally, sugar beets contain much less sugar content compared to sugarcane, so the yield of homemade sugar will be relatively low. For these reasons, commercial sugar production from beets is much more efficient and cost-effective.

Weller heavy gun:

Not used all that often, bu when you really NEED the mega-therms, this will do the job. (Next step up is a giant industrial iron of 500 to 1,000 watts. No, you don’t need one.)

https://www.amazon.com/Weller-D650PK-Industrial-Soldering-Gun/dp/B000TDGI18/ref=sr_1_1_sspa?crid=38JXNN074HTTZ&keywords=weller%2Bsolder%2Bgun&qid=1690735061&s=industrial&sprefix=weller%2Bsolder%2Bgun%2Cindustrial%2C200&sr=1-1-spons&sp_csd=d2lkZ2V0TmFtZT1zcF9hdGY&th=1

Another excellent bit of advice for the newbies to electronics. My heavy gun is an older (but still quite servicable Radio Shack (which Weller made, I believe) that does 150 watts on low and 230 on high.

Something for outside antenna work? I have one of those propane-fired little jobbies. One at the hobby bench and one in the cabling/antenna tool kit. Maybe 200 W worth of power when just filled, but sure beats the snot out of running ac power cords all over hells half acre…

Antennas work best the farther from civilization you get, lol

Weller heavy gun:

Not used all that often, bu when you really NEED the mega-therms, this will do the job. (Next step up is a giant industrial iron of 500 to 1,000 watts. No, you don’t need one.)

https://www.amazon.com/Weller-D650PK-Industrial-Soldering-Gun/dp/B000TDGI18/ref=sr_1_1_sspa?crid=38JXNN074HTTZ&keywords=weller%2Bsolder%2Bgun&qid=1690735061&s=industrial&sprefix=weller%2Bsolder%2Bgun%2Cindustrial%2C200&sr=1-1-spons&sp_csd=d2lkZ2V0TmFtZT1zcF9hdGY&th=1

500 watt iron:

https://www.amazon.com/HAKKO-soldering-processing-HAKKO-MATCHLESS-571/dp/B002MRR6R4/ref=sr_1_4?crid=38NNLP3VCGK68&keywords=500+watt+soldering+iron&qid=1690735990&s=industrial&sprefix=500+watt+soldering+iron%2Cindustrial%2C196&sr=1-4

Biggest one we had in he shielded room business (SCIFs) was a 1kW model made in USA 375 years ago…. (No, you still don’t want one.)

Speaking of Aliens, I got my first VTVM from Mars around 1960. it was surplus and had the name of an AFB in San Antonio stenciled inside it. i’d never seen such a sensitive meter.

They really are amazingly good pieces of test gear. But, with the vacuum tubes, the Fluke does better dropped on concrete, for example!

I must have half a dozen DMMs around in various places, but I always reach for the Fluke 87 first. Wonderful meter and very accurate.

country sodium syrup

Ingredients and Equipment:

Sorghum cane (you can find it at some specialty markets or order online)

Sorghum press or cane mill (to extract juice)

Large pot or pan

Cooking thermometer

Strainer or cheesecloth

Clean bottles or jars for storage

Instructions:

Harvest Sorghum Cane: Sorghum cane is a type of grass with a high sugar content in its stalks. Harvest mature sorghum canes when they are ripe and ready for processing.

Extract Juice: Use a sorghum press or cane mill to extract the juice from the sorghum canes. The canes are crushed to release the sweet juice.

Strain the Juice: Once the juice is extracted, strain it through a fine mesh strainer or cheesecloth to remove any solids or impurities.

Cook the Juice: Transfer the strained juice to a large pot or pan and heat it over medium heat. Stir the juice continuously to prevent burning and scorching.

Skim the Foam: As the juice heats up, foam may form on the surface. Skim off the foam to keep the syrup clear.

Boil and Reduce: Allow the juice to come to a boil and then reduce the heat to a gentle simmer. Keep a cooking thermometer handy and monitor the temperature. The goal is to reach around 260-270°F, which is the syrup stage.

Continue Simmering: Keep simmering the juice until it thickens and reaches the desired consistency. The syrup should be thick but still pourable.

Check for Doneness: To check if the syrup is ready, you can perform a “sheeting” test. Dip a spoon into the syrup, and let it cool slightly. If the syrup forms a thin sheet or thread when poured from the spoon, it’s done.

Bottle the Sorghum Syrup: Once the syrup reaches the desired consistency, remove it from heat and carefully pour it into clean, sterilized bottles or jars.

Store the Syrup: Let the sorghum syrup cool completely before sealing the bottles or jars. Store the syrup in a cool, dark place. It will keep for several months.

sorghum molasses is similar.. you can use your fruit juicer and press for this..

Instructions:

Harvest Sorghum Cane: Harvest mature sorghum canes when they are ripe and ready for processing.

Extract Juice: Use a sorghum press or cane mill to extract the juice from the sorghum canes. The canes are crushed to release the sweet juice.

Strain the Juice: Once the juice is extracted, strain it through a fine mesh strainer or cheesecloth to remove any solids or impurities.

Cook the Juice: Transfer the strained juice to a large pot or pan and heat it over medium heat. Stir the juice continuously to prevent burning and scorching.

Skim the Foam: As the juice heats up, foam may form on the surface. Skim off the foam to keep the molasses clear.

Boil and Reduce: Allow the juice to come to a boil and then reduce the heat to a gentle simmer. Keep a cooking thermometer handy and monitor the temperature. The goal is to reach around 260-270°F (127-132°C), which is the syrup/molasses stage.

Continue Simmering: Keep simmering the juice until it thickens and reaches the desired consistency. The syrup should become thick and develop a rich, caramel-like flavor.

Check for Doneness: To check if the molasses is ready, you can perform a “sheeting” test. Dip a spoon into the syrup, and let it cool slightly. If the syrup forms a thin sheet or thread when poured from the spoon, it’s done.

Bottle the Sorghum Molasses: Once the molasses reaches the desired consistency, remove it from heat and carefully pour it into clean, sterilized bottles or jars.

Store the Molasses: Let the sorghum molasses cool completely before sealing the bottles or jars. Store the molasses in a cool, dark place. It will keep for several months.

https://www.amazon.com/gp/product/B09NPD9WQ7/ref=ox_sc_saved_title_3?smid=A3TAX0K2WG2NP6&psc=1

kitchen gadgets is my weakness

Um, did you really mean sodium syrup? Or was that what I call a typo/TIA?

no lol..dam auto correct.. sorghum syrup lol lol..

country sorghum syrup..

just in case you don’t happen to have maple trees or birch trees around to make syrup for your pancakes..

oh and I forgot the potato mash once you harvest the potato starch you can dry or freeze dry it then make instant potatoes..

Peel and wash the potatoes thoroughly.

Slice the potatoes into thin, uniform pieces. You can use a mandolin slicer for consistent results.

Blanch the potato slices in boiling water for about 3-5 minutes to partially cook them. This helps retain color and nutrients during the drying process.

Drain the blanched potatoes and pat them dry with paper towels.

Arrange the potato slices in a single layer on a dehydrator tray or baking sheet lined with parchment paper.

Set your dehydrator to a low temperature (around 125-135°F or 50-57°C) or your oven to its lowest setting.

Dehydrate the potatoes until they are completely dry and crispy. This may take several hours to overnight, depending on the method and thickness of the slices.

Once dried, allow the potatoes to cool to room temperature.

Crush the dried potato slices into flakes or powder using a food processor, blender, or mortar and pestle.

Store the dried instant potatoes in an airtight container in a cool, dry place. They should last for several months.

Keep in mind that the final texture and taste of homemade dried instant potatoes may vary from store-bought versions. Commercially prepared instant potatoes may contain additives and preservatives for flavor and longevity.

now you can cook the potatoes but before drying or freeze drying take the mash and pot it in your pellet grinder.. if you don’t have one then press it through a ricer

https://www.amazon.com/QCHIAN-Household-Granulator-Pelleter-Processing/dp/B0C5DL1597/ref=sr_1_5?adgrpid=1341405904416154&hvadid=83838152318410&hvbmt=bp&hvdev=t&hvlocphy=106603&hvnetw=o&hvqmt=p&hvtargid=kwd-83838918504854%3Aloc-190&hydadcr=11973_13278497&keywords=pellet+machine+maker&qid=1690745200&sr=8-5&ufe=app_do%3Aamzn1.fos.18ed3cb5-28d5-4975-8bc7-93deae8f9840

https://www.amazon.com/Ergonomic-Stainless-Grinding-Milling-Handle/dp/B08BKKQ2NL/ref=sr_1_4_sspa?crid=CO9F2LD0KYB7&keywords=potato+ricer&qid=1690745268&sprefix=Potato%2Caps%2C256&sr=8-4-spons&sp_csd=d2lkZ2V0TmFtZT1zcF9hdGY&psc=1

then dry it..potato pearl

Lol lol… being poor and still wanting to enjoy the luxuries that others take for granted to still have a quality of life similar to others bas its drawbacks..

the year I had to beat grain into a crude gruel in a cast iron pan with a rock was a real eye opener for me.. heavenly father allowed me the privilege to experience many of the downsides of poverty and I believe a learning lesson..on how to make what’s needed..I’ve had dreams where a catastrophic situation hits.. and I teach others the simple things I know..

long story for my simpleton ways.. my kids have been giving me he’ll that I am not teaching the younger kids what little bit I know.. I said seriously..some of that wasn’t the smartest idea..I did get some shuttles to shoe the little ones how to make fishing nets or maybe a hammock..

not sure if I should show them how to make rope or not..

Suggestions on lessons for the LOOB grands:

1.) Frontier tech lessons are valuable, if for no other reason than it teaches the kids why they want to avoid putting themselves in the position that they have to use that knowledge to survive. Frontier life was a live hard, die young proposition.

2.) Personal savings before government assistance, always. If you can’t put away money into an IRA or a 401K, or both, you are living beyond your means. Equity in a mortgage is a crap shoot as an investment. In truth, debt slavery is about as likely to put you in a tent by the roadside as anything else. When the job plays out, you roll the 401K over to an IRA, always. I began saving when I entered the work force, and it has kept me off the dole more times than I would like to acknowledge.

3. Know when to cut and move on. No income and debt payments coming in are Ure clue to liquidate and go somewhere else (anywhere but the parents basement). Best survival strategy is to build small cash out of pocket, then rent in town when the money is right. I have moved past that to telecommuting, but as to whether that will be available in the future is unknown. Still got the road trip trailer.

“Personal savings before government assistance, always. If you can’t put away money into an IRA or a 401K, or both, you are living beyond your means.”

I sound like a broken record on that N.. the other thing I tell all the grand kids is to invest the same amount that is taken out for Social security and put it in savings bonds.. then flip them on the maturity dates for more.. with just what I paid in out of my paychecks I would have had around fifty million in savings if I could have directed some or all of the companies portion I would have had about a hundred million…. a kid invests in that until they get married then life takes over would still have over a million at retirement age.

the problems I had was I got sick.. and every penny had to be used for medical.. the year we went without an income took the rest..all those free money programs..well they aren’t for citizens that own a home or a car or more than one car..see you can sell them all and live off of the proceeds..

my ex wife had same day surgery the same time a gentleman from my church..same doctor same day .. the difference. he had insurance we didn’t long story but the surgeons bill alone was two grand more than his total bill..

I resurfaced his city block parking lot in over hundred degree heat by hand..( that’s how my wife and I became friends. she had a similar issue from having a stroke they took every penny except 5 dollars) the hospital..that was another story.they called every half hour.. said stuff like why did you even think of seeking medical treatment if you didn’t have the money to pay for it.. they called my bosses mother in law.. I was feeling sorry for myself then seen a quadriplegic wo.an crying. she was a housekeeper at the hospital. worked new years eve. got smoked on her way home by a drunk driver. after months of care she survived..the hospital insurance she had refused to pay.see it was an accident not an illness. the drunk didn’t have insurance..they jumped into her account and took e very penny out except ,.75 cents..

I begged for forgiveness let me work it off.. they told the religious people to who e that idea up their asses.. I apologized for the way the business office treated them. and I said I only wanted to keep my integrity. then said I sought medical help because of the hospital mission statement.. she said one minute.. she called right back and he’ll year began.. hell year I worked three full time and one part time jobs..140 plus hours a week.. I screwed up on two weeks where I didn’t even have any time for sleep.. I was terrified I would die when I finally went to sleep.. had them watch me to make sure I didn’t die. ( my best friend attempted that..I said take a look at what it had done to me..that was on the Saturday before easter. Tuesday after he got off of work. we talked he was so tired he was going to lay down. he died from a heart attack)

I had the what if disability policies on everything.. my favorite responds was. we quit accepting claims at noon yours was received at 12:15 please re submit. they wouldn’t accept claims unless they were mailed,emailed,sent certified mail and the state board of insurance sent it in. the only one they paid on was six months of house payments at the bank.. the reason they paid that was memorial day.

it was that friday..I was still in a wheelchair and I had efax.. the claims were all on computer so all I had to do was print or send them.. the exact went to the insurance company and the state board of insurance.. the bank called and asked if we had planned to continue living at home..yes..

well the Insurance company was refusing to accept the claims..so I hit enter and it came back there is a connection problem try again..so I tried about every three minutes..lol for three days even had the cable company check the internet.. Tuesday morning..8.05 am we get a call..don’t send any more from the state insurance board.. five minutes after that the insurance company called saying the same thing.. that was the only one they paid on..I tell the kids don’t waste your money..those are only good as long as you don’t need the coverage or you stub your toe..anything serious forget it..watch the movie the rain man.. the movie doesnt do the true horrors justice.

we are still struggling with trying to rebuild some savings.. but the medical industries business model doesn’t allow it.

I help others facing downturns in life. my last guy.. his wife was a nurse had the insurance..of course she got sick. cancer. they of course fired her and she lost the insurance.. they took his farm his rental home his thoroughbred horses his company and all of his belongings to pay for her end of life cares.. nursing homes have the largest divorce ratings.. they have to get a divorce just so the surviving spouse can still have something to live on. you would fall over if you had seen as many surviving spouses living in their cars.. I use to walk out have them come in and make up a couch or bed if any are open..then get them up.. I had an attorney general that broke down in tears..

one of our guys living in our spare rooms was an engineer.. had more degrees ..he designed and was responsible of tbr built deepwater oil drilling rigs. there was a huge explosion and horrible spill.. because of Katrina he lost his million dollar home..the insurance companies paid a penny on the dollar..the explosion and spill had him brought in to give testimony with congress..he told the truth and was black balled.. like those giving testimony y about the family corruption.. they to won’t be able to get employment.. how he came to me was he was homeless in his car..his car broke down and he had gotten sick and in the cardiac wing .. he couldn’t accept what happened to him then in our spare room..saddest thing to..smart man couldn’t get a job cleaning dog pens..his famIly dumped him..once he wasn’t making any money it was over..

it doesn’t matter what station you are..when the one two three strike of fate hits you its done.

millionaires shoved to poverty. I teach my kids and grand kids so if or when it happens to them they can still have a quality of lice.. nursing home care is a quarter million per person per year..30 Tylenol is 500 plus per month .. medication are tens of thousands percent more in the usa than anywhere else..

I have been there done that..the hardest time was watching my wife..brave face..let go because of our medical expenses they looked for anything at all.. she had 30 years working devoted to her job.. late at night me in a wheelchair and when she thought no one would notice..she would breakdown into tears of frustration.. couldn’t get a job and putting in thirty or more applications a week..

we went a year.. we had some savings and I insisted on having a years food.. so we could at least eat..what was shocking was everyone you think will be there e eh for emotional support was just like our engineer.. they treated us like we had the plague..family and friends gone..

the same thing happens all the time.. I feel privileged when I can lend a hand up to those facing the same thing..

“Frontier tech lessons are valuable, if for no other reason than it teaches the kids why they want to avoid putting themselves in the position that they have to use that knowledge to survive.”

that is true and not true.. I sometimes question whether or not it would have been wiser..

my average work week was a hundred hours a week. I didn’t ask for any of the good Samaritan probtams..I had two strong arms and legs.. I’ve never been on a vacation.. one working at the hospital they hire you at a point whatever..I was a point five which means they o my guarantee you five working days.. you had to go d your own replacements.. since healthcare is the career of long hours and working short..well good luck with that lol. lol the wife and I was just talking about that at coffee lol..

I accumulated my maximum allowed so every year I could give vacation time away and would donate two weeks of vacation time to someone out with an illness..

that is where my obit comes from.. loob went on vacation. loves his family and friends very much and hopes the weather is good and moderate temps.. hopes to reconnect with everyone again someday..

people that know me would stop and ask where I went..then they can go to chicken ranch get a keg and give each of the kids a roll of quarters for the video games..

its funny though.. my daughter had surgery I took 4 hours off to be there.. I got back ( they go by the point sysrem 16 hours missed your in trouble) well I had jury duty twelve years before..I get back and they were ranting and raving wrote me up and said they could have my job if I did something like that again.. I thought to myself ..well why not take it now.. and gave my two weeks..I went to drive the garbage scowl..three months later my new boss at the time ran into my old boss.. the old boss told him..if we had ever really known how hard I worked. they wouldn’t have ever done that.. later I fell thirty feet got busted up real good..

anyway several weeks into trying to heal up.. my new boss started ranting at me because he had to do my job.. I went to work in a cast ..then later ragged on me because I had to work two full time and one part time..( after insurance I only made 307.00 A month) so I went to get a private policy..long story I ended up without insurance.

ended up leaving to work full time at the hospital after he’ll year..my boss could t find anyone willing to work and left his job. he now drives semi..y ex we are still friends he told me last year he regretted making me dump the insurance.. and the closed the place down..

now my daughter.. she’s a hard worker..even though I detest insurance companies two of my girls are agents o e runs a small agency the other the head of a department in a big agency..

the one that runs a small agency has been running g it since 96.. the owner got the agency from his father..doesn’t really have any interest in the company or the clients.. what he told me is he loves the money..she has no benefits no insurance etc. well my grandson needed surgery she took off to be there while he had surgery..

the owner of the agency threw a fit..screamed all week.. ( missed his tee time ) and she told him quit screaming at me and don’t make me choose.. then the plastic surgeon good get him in today.. she told her boss on Thursday she needed today off to take him in..the guy went. allistic.. ( he has a life to and its her job to run it) he threw a stapler and hit her in the head with it..she said that’s it..I’m done this is your two weeks notice..

now I know my girl and I know she goes above and beyond..so will he have to close down his small agency.. guaranteed younger employees won’t tolerate his arrogance.. and a licensed agent can make quite a bit more than what he is willing to pay.. the policies she’s written in guessing the may follow her..

she to won’t seek any of the programs..and will be employed if she already hasn’t taken another position..

I suggested she start her own agency after twenty years she has a good deal of clients..

I have to do about twenty pounds of peppers and fifty pounds of onions for this winter.. if you do onions don’t ever freeze dry onion slices.. by taking a mandolin slicer and making thin slices.. never do that.. that is crucial.. especially sweet onions..

if you do it..you will take and eat one.. I did that and before I knew it I had eaten twenty pounds of onions..

they were better than any potato chip ever..

Now I have to go off and do a simpler job: Removing bulb bases from broken bulbs in a couple of light sockets at a friend’s house.

Just for anyone that cares, or needs to heat a chicken coop, regular incandescent bulbs won’t be legal to sell after tomorrow! If you need them, get ’em while you can.

Seriously they are going to make Incandescent light bulbs illegal.. my god..Has everyone gone mad

Damn! There goes my Easy Bake Oven…

You know we have one of those for the great gran daughters.. and if the get gas appliances outlawed well hell..

all this griping about fossil fuel appliances and cars then you see scrap like this..

https://www.rt.com/news/580573-nuclear-war-blinken/

There are times when I believe Joe Biden is the brightest bulb in his administration.

Then there are times when I’m sure of it…

George

The Heathkit IM-13 must have been a popular beast! There are several YouTube video’s on how to restore it.

Very good column today!

I’m working a regulated power supply that had me flummoxed. Ham friend found his Kenwood PS-53 suddenly putting out 20 volts DC instead of 13.8. ‘Easy Fix’ I told him. It just lost the regulator. The supply has two 25 amp pass transistors in parallel. They need to be well gain-matched, but the supply is rated at only 20 amps, so they should loaf. These transistors are good. There are two other driver transistors for these that set the voltage. Both were shorted and replaced. Still the unit puts out full 20 volts. Probing further, I found I was unable to set the voltage with the indicated pot. The Japanese designers were parsimonious in selecting the fixed resistors for the voltage divider that the pot is in the middle of. One-eighth watt little grains. When the transistors shorted, a lot of current went thru these little rice grains and I found they had ALL changed value radically.

So replaced all the resistors with larger 1/2 watt jobs. Now loading the supply up to 10 amps, I can adjust the regulated voltage down to 13.4 volts…. but unloaded the supply still puts out full 20 volts. WTF? I was working from a schematic with sparse voltage readings at some circuit points. The only way the supply would ‘know’ the current loading would be the base current drawn by the parallel pass transistors, so I was looking closely at that driver transistor circuit. At full 25 amps the base current could be as high as 7 amps input… kept at regulated voltage.

Serendipity sometimes happens. I was gifted a Kenwood TS-450 rig with manuals, and I found the PS-53 schematic with setup procedures and specs also in the manual. I was stunned in reading the specs that regulation is guaranteed from 2 to 20 amps…. BUT NOT BELOW. It said to test open circuit voltage at 16-20 volts. The design is such that the regulator does not kick in until you draw more than 2 amps from the supply!! Why Kenwood designed it this way is beyond me. I can think of lots of equipment damage from over-voltage if this supply is lightly loaded.

Anyway, it pays to have a GOOD, COMPLETE manual that indicates these things. I’m now in the process of setting the overload trip point and giving the supply back… with a stern warning about usage. Apparently it works OK to power the Kenwood radios, which use more than 2 amps.

“But George, you idiot, I don’t HAVE a VTVM!”

Yeah, me too.

Six or seven maybe, but not just “a VTVM…”

Lol lol ..nothing like having spare parts

Dude! I have a dozen Akro-Mills small parts cabinets full of new parts — six or seven of them filled with capacitors. I will re-use a (tested-good) carbon resistor without hesitation, but I never re-use a capacitor. If I have to change it, it’s gone. When one is leaking it MUST ALWAYS be replaced. If I’m working on something vintage I’ll drill out the old cap (capacitor) and put a new one inside its body whenever I can, (be kind and tag the underside of the chassis, so the next owner doesn’t start replacing those “old” axials) but even the ceramic caps can get flaky over time, so capacitors are either re-formed (think of it as “re-programming” or “re-educating” the capacitor) or replaced when they can’t be formed back to spec, or when they explode…

“if you took a radio course in the late 1930s, there would be plenty of teaching passed on about how to “restring dial cords” and whatnot.”

Ugh! The first time I did one I was about 7 or 8. PITA for a little kid…

I did that string job for my father.

He did the: “Son, my fingers are too large to do this. They don’t fit. Will you do it for me…?” thing.

This is called “home schooling” and was common, amongst our predecessors. Until they hit the rebellious stage, a child will damn’ near kill themselves to help Mom or Dad, especially if they’re given a reason why their specific expertise is needed to complete the task, at hand.

It was not until I had kids of my own, that I realized Dad could probably have restrung that dial in 1/20 the time it took me, but had he done so, I wouldn’t have learned how to do it…

“It was not until I had kids of my own, that I realized Dad could probably have restrung that dial in 1/20 the time it took me, but had he done so, I wouldn’t have learned how to do it…”

that was my parents..you never told mom that you were bored..if you made that mistake you were so busy..

I once made a comment that I wanted to make moccasins.. the next thing I knew..dad was dragging home a cow hide…

“Never work with leather shoes on. Leakage to ground is possible. If in a chair, plastic casters and dry mat. KEEP ONE HAND IN YOUR POCKET”

I was always taught to work with my right hand and keep a finger of my left hand wrapped around the belt loop in the middle of the back of my pants.