Yeah, well…since we do call this the ShopTalk column, every once in a so-often, we like to actually build something. Big, important, flexible, resilience oriented toward local manufacturing and sustainability builds.

What we’re doing today is a whole “soup to nuts” build of a Sainsmart 3018 Pro CNC that I’ve had sitting in the project queue for almost two years, now. But, it’s virtually identical to the Sainsmart CNC unit for $164.00 here on Amazon.

Need to spend more money? You bet, big spender! I also picked up the Genmitsu roller X-axis, which looks like a nifty device to be able to photoengrave glassware and the like. Maybe make some of those photoengraved lampshades, while I’m at it!

Oh, but that ALSO means some long green for at least a 5.5 watt laser cutter plugin, too. And if you want to cut thicker material than, oh, a manila folder’s worth, you can really go crazy with a Laser Module, LASER TREE 20W Optical Power Laser Engraving Module with Air Assist, Quad-Compression Spot, 80W Laser Head. At $559 a copy, you’ll want to be SURE to click the $80 off coupon!

The 5.5 watt laser is all I was planning on, but shops are like boating. You start with a small canoe or kayak in an apartment and next thing you know you’ve got a mortgage, a boat, and country club dues. Which is, sport, the American Slavery 2.0 deal. So be advised.

One final point: Lasers have two power ratings. Power-power ((say 80 watts)) and “optical power” which is 25% of that, so 20 watts. Honestly, I don’t understand all I know about this, except more money usually means more capacity.

But we’re in this for education since at 74 I’m not in a great-big huge-ass hurry to run out and buy a humongous CNC waterjet machine.

But let’s back up a bit, old pard. Maybe you need a short…

Orientation to CNC

Let’s begin with some ground-state knowledge that will be useful both in CNC and in its half-brother 3D printing.

- All these basic machines either a) cut-away material – like the CNC cutter bits called “mills” do. (They are sharper’n shit, so be careful!) Or b) in the case of a 3D printer, they have a geared printhead where the CNC spindle/cutter motor would be. In 3D printing, low temperature plastic filament is snaked into the hot printhead and “squirted” (very precisely) on to a super-flat “build platform.” Additive fabrication is done with 3D while subtractive work is done CNC. Simple, right?

- Both types of machines have a rectangular base on which a build platform is pushed around by “stepper motors.”

- We call this discussion an “orientation” because each machine is programmed using 3-axes.

- The left-right movement is done by the spindle on the “gantry” assembly. This is the X-axis.

- The towards, or away from you, movement is handled by the bed (or in 3D the build plate). This is the Y-Axis.

- The up and down of the spindle (or in 3D printing, the printhead) is along the Z-Axis.

When you are out shopping for projects to make on the web, it’s useful to remember that CNC files typically have file extensions like .NC (numerical code) or .g-code which is GRBL cutting machine path code. ALL3DP (an excellent and useful site) has immeasurable details at GRBL Software: All You Need to Know.

You will be thrilled to discover that when you want to cut lots of high precision material, you’ll be right at home with a waterjet machine. Because they are very similar in design to the CNC machines. Well, except in place of spindle motors, they can have 3-trillion pounds of pressure out of a needle-sized water nozzle which can tear through anything. Flow makes dandy waterjets (out of most hobbyists budgets, except maybe Jeff Bezos who we happen to know is a hands-on shop kinda guy. Take a look over here for more on waterjets.

There is, I think, a range in 3D printing, CNC, and Laser engraving which is a “sweet spot” for the home hobbyist. We’re thinking 400 mm x 400 mm x 400 mm on the 3D printer machine, maybe a 6040 CNC with a 100 watt/25 watt laser for cutting thinner sheet goods. For anything bigger, go visit my friend Jim Lewis over at https://emachineshop.com. They can fab up all kinds of neat stuff. (I did a little consulting for ’em years back and they’re still in business – look surprised, lol!)

Workplan Today, Workflow Later

Our “recipe approach to knowledge” has proven extremely useful over 60 years of field testing. Basically, the training comes down to:

- “Take all your problems in life…,”

- Create a Solution (nice and graceful solutions are marvelous)

- Make a Gap List (tools or things you need) then collect to fill the gaps.

- Make a workplan. With all the parts, what are we going to do with ’em?

For Today’s Build…

- Workplan is unbox and envision.

- Assemble physical unit.

- Wire physical unit.

- Softwarize physical goods to imbue them with “life.” (Coding being what Frankenstein would have done one he figured out the details of electricity, right?)

- Make some things.

- Find a design

- Create NC or GRBL file (or download off net)

- Load to dedicated computer or offline controller

- Load (clamp in place) your material

- Start the machine and supervise to ensure pathing is good.

- Dust off chips once in a while.

- With laser, avoid starting fires.

In the advanced part of this build – which will be a long in a month, or so one hopes – we will replace the spindle motor with 5.5 watt laser and hopefully, without setting the place on fire, we can do some wood burning and etched glass work, too. But you should see the “big deals” about CNC, Laser-cutters, and 3D printing.

We’re all Junior Gods in Training here and it’s a huge rush to be able to add these kinds of skills to your personal skills inventory. After you master stock trading, chasing two-legged bunnies, driving hot cars, flying airplanes and sailing boats…..er…where was I?

Step 1: Open Box

How hard can that be, right?

This is incredibly good packing but useless when comes to project building, so I tend to dump it all out on the bench.

Please notice Ure’s arrangement (by pile) method here:

I will be working right to left in the assembly. That way, the right hand is not pushing crap onto the floor. I keep my tools on the right (about where the instruction book is) so there’s no extra reaching involved.

Since we’re all geniuses, we think the first used parts will involve some hardware and flat metal pieces along with the two lead screws and four solid track rails. The next pile left is the spindle assembly. Further left of which are the electrical components and cables. And far left is the software if included.

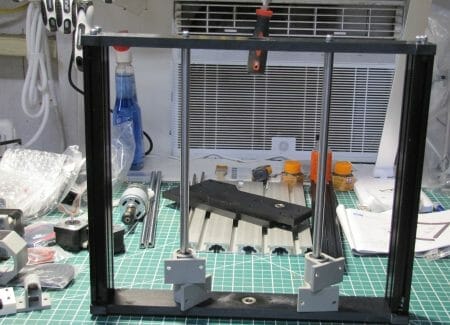

Step 2: Bolt Frame Together

Not rocketry. But don’t get carried away tightening anything. Leave everything semi-loose and easy to adjust.

The reason you put the Y-axes track rods loosely is because in the next step,. you will install one of the stepper motors. And a coupler, and then insert it into the frame, like so:

Motor is at the bottom and the blue whizzy isthe coupler.

Next, you’ll install the base plate which is on sliders (outside) and a drive screw in the middle:

You will see a copper special nut-like thing (above left in this picture) and that’s the anti-backlash mechanism for the bed. There’s a “regular” drive nut on the far side, a pressure spring in between, and this “special” nutlike thing with wings that fit in slots.

Don’t get too worked up over making things track yet. You’re probably wondering “Why?”

What no one seems to mention is that THE DRIVE SCREW IS IN CHARGE.

Seriously: The easiest way to get a “good build” is to be meticulous about frame alignment. I’ll show you on the X-axis (up on the “gantry”) in a sec.

But to do that, we need to cobble up one of the side pieces (right side) and install the second stepper motor, coupler, and drive screw:

The top and bottom holes on the back of the spindle carriage fit into the solid rods. With the drive screw in place, the left-sidepiece is secured, and I have one top rod bolt to install here…

See? This ain’t so hard – even an idiot can do it. As I demonstrate.

Now, before tightening, but with everything in place, you run the spindle all the way left, with drive screw in place, and let the carriage align the track rods where it wants to, then tighten. Then hand-turn the drive screw to the right side and let things wriggle into place. No wriggling and screwing jokes, please.

Now, you return to the bed and with the machine upside down, you run the bed all the way in (tighten that end a bit). Then hand turn the drive screw to the other end, repeat. Go back and forth, getting tighter each time.

What you’re after (all this screwing, right?) is roughly equal and not much resistance. The more time on this part, the better long-term results can be achieved.

Wire This Puppy Uppy

So, you get this controller box. It has all kinds of connections on it, but everything is clearly diagrammed. Gantry X-axis goes to the middle right as you see. The Y-axis is left of it. The [white] empty plug is where the spindle plugs in, while the brown two-wire connector is where the (optional, hold onto your wallet) laser cutter plugs in.

Next, you have me going crazy with tie wraps. Being a fanatic builder, and all…

Eventually the get trimmed and first thing you know we’re almost ready.

Make sure you hand-twist the drive screw all the way in both directions on the X-axis to ensure that wires clear:

Once that’s done, you plug in the offline controller and start running the axes out to make sure they are operating smoothly.

There! How about that? Simple, Quick, and very useful.

Or, at least it will be, as in coming weeks I get through all the self-learning on software and get it moved into position (along with remember that $210 1TB Win-10 i7 machine?) with a dedicated computer.

This post, for convenience, will be posted over on my https://ultra-make.com site which has been a placeholder for this kind of project….

Now, somewhere in here, the lawn has continued to grow, so that’s next up on the shop schedule for the day….

Next weekend, if he can stay motivated, the Radio Detective will be along as we tackle some of the long-delayed ham radio projects.

Write when you get rich,

George@Ure.net

“I keep my tools on the right (about where the instruction book is) so there’s no extra reaching involved.”

What tools?

https://www.youtube.com/watch?v=UBAlsEkZ35o

George

OK!

You have these great new toy’s, I mean tools.

Go build yourself a robotic lawn mower!

Don’t forget you will need some kind of microcontroller to make it work.

Have a great day!

see what’s the real need for a robotic lawn mower.. similar to getting my first television with a remote.. telling a coworker that I had one his response was I don’t need one..hunny change the channel is much cheaper lol..hunny the lawns getting high.. the book Tom sawyer made this popular with fence painting.

Um, in the second photo what is the drinking glass or tumbler looking object just above the manual? Is it part of the machine?

Actually, since I now drink scotch for health reasons, it was purified water.

Cool. I have a hydraulic manifold on the Allis that needs 2 bushings and several connector links repaired/replaced and some actuator rod links on the Baler that need replacement. All of these are high strength plastic parts for control arms. While not outside my realm of capability to repair the jobs require major disassembly and these small parts are almost impossible to find unless you purchase the larger part groups with them already attached at the factory. Which I have no doubt is someplace called China.

Admittedly, setting myself up to manufacture this handful of small parts would cost more in my time and expense compared to purchasing the part groups but I have several neighbors and cohorts with similar situations. I spoke with them at the last Executive Committee meeting and we came up with an idea to approach a local VoTech Ag class to see if this would be something feasible for them to do or possibly get directed somewhere else. There was a news item about them and 3D printing that caught my attention.

No doubt we cannot get this done in time for this season.

Several of us are leasing a baler this summer but that will bite into our budgets.

Stay safe. 73

Good thinking on your part to hit up the local ag class for your project. They should be highly receptive to the idea of helping out the farming community. Only potential drawback might be the ethics of duplicating commercially available parts. However, if they’re not selling those parts on the open market, that issue might not arise.

They’ll need the old parts for measurements and the specs for new part dimensions, but that shouldn’t be a big deal.

“Good thinking on your part to hit up the local ag class for your project”

I use to do that.. give the car to the local high school or trade school for a project.. lately in the wastelands.. they do it all in simulation.. no hands on work.. and in the high school shop class is now non existent..

I could tell you about my google mechanic that I took the buggy in to get a power steering hose.. omg.. twelve thousand later.. I dumped the buggy.. the kids didn’t know anything and of course I had to pay for everything.. it was a nightmare.. Mecanically that van would have lasted me the rest of my life.. the new mechanics today are not taught on real cars.. google says this is what it needs.. it doesn’t matter if you can see the hose leaking..

I told the kid.. the last time I took it in.. where is my coupon.. he said coupon.. yes in the wastelands and you working on the car.. if it doesn’t have brakes and steering your a dead man.. I need my coupon for a free casket..

If’fn the kids have a high-temp 3D printer, they would have the ability to help you. I would want at least nylon, which requires a higher temperature than other plastic filaments, or carbon fiber (which I believe would require casting, and possibly machining. I don’t know, but would research if need arose) because I hate doing a job twice — but that’s just me…

George, found this earlier this morning, thought you might find it useful.

https://revealproject.eu/journalist-decision-support-system-jdss/

First, and foremost, Happy Mother’s Day to all the wimmin!

My Mom liked purple(s). I have a lilac flag and fly it every year from her BD to MD. It’s a short run this year. Apparently someone visiting the lake asked Mrs. Egor about the flag and was crushed to learn it’s purpose. Guess he thought he’d found his people. Uhm, no …

It was my plan to do a few things for the Mrs., knowing she’s pining for her boy today (like every day but especially today). Yesterday I restored her laundry room. Hero move, and a win-win. Sigh, gate valves don’t get enough exercise. Drip. Try again.

While media magicians gesticulate about gas ranges, and power plants … here’s a nightmare for ya:

https://oilprice.com/Energy/Energy-General/American-Petroleum-Institute-Claims-The-EPA-Is-Trying-To-Ban-ICE-Vehicles.html

You’ll have to pry my cold dead hands off the steering wheel.

Five years or less we will axe: what were we thinking.

You read it here first.

Egor

ps – George, take an afternoon out of petty cash. Kick yer feet up (as shall I).

cool tools Mr Ure,,, but there is some ancient Egyptian granite ware that expresses advanced math and precision of manufacture, have a little look see, but is just a small vasa

https://rumble.com/v2nhndd-were-ancient-computers-used-to-design-this-artifact.html

can you match that? but, but, but, we are the most advanced creatures of evolution, that is what ure/our schools teach ya.

as history is re-written by the ??? who?

Happy Mother’s Day,,, we all have one,

people with birth canals

that is real mothers, not fake trans-non-mothers, mentally sick individuals needing serious help and or Quarantined,,, to protect the children from them

“It’s Mother’s Day in the United States. Which has led a plethora of corporations and consumer brands to advertise their products to the most important women in our lives: our moms. Unfortunately, some of these brands have decided that your dad can now be your mom. Or that some random dude in a dress can be your mom”.

https://thenationalpulse.com/2023/05/14/its-mothers-day-so-of-course-these-7-corporate-brands-are-promoting-men-in-dresses/

https://youtu.be/qoaHWeiiWa8

https://youtu.be/oY92oo-DpmM

https://youtu.be/3CPMXeuSWq4

Now.. I talked to Dave.. at the Geopolymer institute several years ago.. and some of the guys working with him.. on his theories of poured stone.. so is the jug made from a carved stone.. or is it a molded piece..

several years ago I made the horrible mistake of showing the kids how to melt stone using the sun.. the idiot that got this idea.. had thought boy the kids should know that stone could be melted and molded to make pieces.. unfortunately the kids had other ideas and was melting everything they could find.. needless to say I freaked out.. took it away.. we changed what was to be taught to the kids.. as in how to use the heat of the sun to freeze water.. and we made the solar beer chiller.. ( it was awesome.. gave it away after a couple of years ) I have always wanted to build a rammed earth home.. seen one made by the college back in the forties.. the thing was amazing.. and durable.. dam nice.. I need a new trash can container.. and wanted to do the rammed earth for it.. ( the son in law wants me to make it out of wood.. I wanted to make a storm shelter out of it.. )

you can turn stone and shape stone.. ask nancy she is a master at it.. makes some of the prettiest stones for jewelry ever.. ( My favorite is rose quartz.. got it all over .. love it… and our home is quiet.. no stress here) crown jewels.. ask G about the light crown and the benefits of it.. I totally am sold on it.. My mother was a crystal and stone believer as well.. I picked it up from her.. never knowing the reasons why people had precious stones..

now we know we can write information into stone..https://futurism.com/memory-that-lasts-forever-new-quartz-coin-can-store-360tb-of-data-for-14-billion-years

I believe that it was more than likely a cast object..

“ancient Egyptian granite ware that expresses advanced math and precision of manufacture, ”

I will never forget my first piece of furniture.. a friend of my parents.. use to work with Walt Disney as a cartoonist.. when ole walt was first getting started.. he split off because walt didn’t want him to go on a honeymoon.. and he settled in the middle of the wastelands.. anyway.. we needed a couch.. and visiting with him..I made the comment on how expensive it was.. he said what is so tough about a rectangle.. anyway.. my first piece of furniture was made out a cardboard.. I have been struggling with making a violin out of paper.. the problem I have is.. the pressure of the strings collapses the neck.. so the neck will be wood.. I have gotten a great deal of help and advice for it from both grady and mr. Russ in Italy.. I totally plan to show them both the finished product when it is done Mr. Russ has said he wants to see the finished product..the biggest thing was measurements.. the thickness and tuning the blades.. how do you tune toilet paper..sounds like a shizty job there LOL LOL.. oh and I hope that charmain will be sqeezed lovingly LOL..I am getting excited.. just got my patterns the other day..for the one part that I wasn’t sure of…. both make violins one as a profession the other as a hobby..

My sisters husband helped invent some kind of laser beam printer thing. He’s dead now and she’s a millionaire. And No, she doesn’t lend out money. Oh well, think I’ll get the leaf blower out and clean up my pickup. Interesting hobby ya got there George

People who hang out at Urban usually do have interesting, well, EVETRYTHINGs

One of the characteristics of smart people is our wanton disregard for conventional boundaries of thought and action. Very fesarful stuff to the weak but clinging to control types, but useful now and then to achieve the “leave me the ‘f alone to have my peace in your f/u world” objectives.

I know what you mean! I’ve been a beekeeper since I was 11 years old. Amazing little creatures. Nothing de-stresses me like sitting about three feet away from a hive and watching the bees! Sounds a tad weird, but for me it works! When you’re almost seventy years old, ya take it where you can get it!! Lol! And Happy Mothers Day to all the Mothers out there!!

I do want to get a cnc printer.. and a laser etcher..

Years ago during the Reagan Recession.. jobs were tight.. to provide for the family.. I used my training in photo school.. and physical labor.. I would use a UV resist similar to making jell plates for printing presses.. and transfer photos onto glass for mirrors or entry door.. someone gets a good hunting scene and forever have it etched on the glass..

back in the military all I had was a diamond pen.. ( right in front of me in the bottom drawer .. and it was a big hit.. use to make beer mugs.. LOL the physical labor well that was a little of this a lot of that.. what ever was needed.. and I did stain glass work.. one restaurant had me do an entry glass.. I was disappointed when the wife and I went and they had taken them down.. only to be surprised that they had them framed in the dining room ..

the learning curve.. I would have to learn how to use the equipment..

but it does interest me.. making parts to things I create in my mind would be wonderful to play with.. I have way more ideas than money LOL.. I wouldn’t have to take the ideas to the laser cutter or foundry to get them made..

Nice work…

Water jets are a sore spot with me. I’ve twice had an opportunity (before you opened the “Hot Deals” page) — 6×6 ft and 8×8 ft, full CNC (3D on the 8×8). The first was at a fab shop east of Columbus (Ohio DOT, maybe) and sold for $2600. The second, however, was in OOW Steve’s back yard and sold for frickin’ $200. I had no way to move a precision machine that big and weighing over a ton, and no place to put it, or I guarantee you that one’d be mine.

If you wish, it is something else I could put on a “George’s toy list” for if/when another ever comes up…

Not only is it that big..but where do you put it….

my wife made me dump my books because she wanted to park in the garage..

Sorry for the off-topic post, but I want to throw out a shout to BIC (at least I think he’s the one) who mentioned taking collagen for the pain in his hands.

THANK YOU!

After taking Nabumetone prescribed by the arthritis doc for 15 years without much improvement, I started taking collagen a couple of weeks ago after reading his comment. I’m thrilled to report that my hands no longer hurt 24/7. They’re still a little stiff, but I can now make a fist without grimacing. For someone who enjoys working on stuff, pain-free hands are a godsend.

3D printing … the new frontier in high tech manufacturing!!

WAY out of George’s budget … but GE’s new turbine engine (for small turboprop aircraft – named “Catalyst”) uses 3D printing for making many of the key elements of the engine, including the combustion chamber and all of the ducting within the engine. By doing that they are cutting the “item count” for their new small turbine engine quite dramatically. Not counting the blades and gears the part count inside the engine is reported to drop from about 890 parts to 35 (compared to the existing generation of small turbine engines).

YEP they are 3D printing METAL PARTS!! Super high alloy titanium metal parts.

By 3D printing they can make the part more complicated on it’s insides than what could be done via traditional CNC milling and traditional casting techniques, and what used to take a number of parts bolted together can now be done by one single part.

Sounds great but all has NOT gone well with the new GE 3D printed engine.

In order to avoid US Export Controls wrt the finished engine it was/is being totally designed in the Czech Republic by the engineers over there (GE had bought Walther which made very respectable turbine engines for use in Soviet Block airplanes so there was very good engineering and manufacturing expertise in the Walther division in Czechoslovakia). The problem with that approach of trying to keep the engine away from US Export Controls however has resulted in the situation that as the engineers in Europe ran into problems with this new manufacturing technology and designing a new engine around that, remember this is a FIRST USE of this technology anywhere on this scale and complexity, they could NOT consult with GE’s engineers in the US … since that would render the engine subject to US Export Controls which was the whole point of designing and building the engine in Europe to begin with.

The original 2018 completion date for Certification of the engine slipped to 2019, to 2020, to 2021, to 2022 and now GE hopes to FINALLY get the engine certified for use by the FAA and the Europeans in 2024 … but DON’T count on it!! In looking at the numbers I don’t see how the engine will EVER be profitable for GE even if they manage to keep building it for a number of decades since the overall market is a low volume market. GE has invested buckets of money into this engine ($1 billion at last count), I read somewhere about 5x what they had planned to invest in the engine – and still do NOT have a certified engine (as a spillover the lack of that new GE engine has kept Cessna /Beechcraft from producing it’s clone of the very successful Pilatus single engine turbo prop aircraft which they were supposed to start selling in 2018).

Anyway … the technology of actually using 3D printing to do most of the manufacturing of a high tech, high temp /high pressure, internally very complex engine is a real technology changer. Once GE finally get the wrinkles ironed out wrt their manufacturing problems (multiple redesigns of different parts of the engine had to be done) I image that they will use the technology to start to make other complicated parts for their entire line of aircraft engines via 3D printing.

S2, thanks for the interesting post!

I wouldn’t underestimate the Czechs. I visited Expo2020 in Dubai in 2021; many countries had pavilions displaying their leading technologies. I was blown away by only one: the Czech robotics display. Lots of smart people there!

A 3D produced turbine may be an expensive lesson, but like our space program’s fallout, I bet the payback will be manyfold. Aircraft engines now, but then hips, knees, missiles, and car parts?

GE’s been producing several of the engine internals for those engines for years, in a 3D printer. ‘Problem is, they can’t produce any of the “stress pieces” and pass certs, because those pieces have to be both hard, and not-crystalline. You can 3D print bits & pieces all day, but you can’t print forgings. The hammer not only hardens, but also aligns the molecules linearly, eliminating crystalline brittleness. Crystalline metals shatter along the facets, on impact or sometimes on either deflection or torsion. Hard metals (at least steel and titanium) flex, then return to their given shape.

3D metal printers that’re of any account, start at about $240k, so y’all can quit dreaming about manufacturing those M-16 lower receivers. I have seen exactly one come up in the surplus market, and it sold for more than a new South Bend lathe…

Well if you are lucky that CNC machine might even work! Mercury leaves retrograde today and resumes forward motion.

George,

The Nikkei is putting in its terminal day gapped lower high valuation Monday 15 May 2023. This is its terminal lower high valuation peak. It peaked at 29629.47, over 9200 lower than its absolute peak on 29 December 1989 at about 38915. Inflation adjusted, its current value is much much lower.

Shave off 33 years and we were relatively young guys in 1989.

Is it America’s turn to have a 20-30 year period before the November 8 2021 Wilshire is exceeded, (not adjusted for inflation)?

The March 2020 weekly fractal count for the Nikkei is 33/72/63 weeks peaking in the 63rd week with its May 15 2023 saturation exhaustion growth gap. The 72 week second fractal is composed of 14/30/30 weeks. The current 63 week third fractal is composed of 15/30/20 weeks. The 20 week final growth fractal to peak is composed of 8/18/16/11 days, 3/6/8 days and 5/12/10 days with the exhaustion gap on day 10 of the 5/12/10 series’ third fractal

A collapse over the next 6-7 trading days starting Tuesday 16 May would complete a 5/12/10/7 day 4 phase fractal cycle.

George.

One more day for the Nikkei … for a 5/12/11 day final blow-off.

Another exhaustion gap.

The 11th day of the third fractal of this 5/12/11-12 series had another exhaustion gap and with 45 minutes left in the trading day may end at low on the day for a quasi key reversal day.

The crash decay sequence for the Nikkei is likely 7/17-18/17-18 days starting on 16 May 2023.

I’ve got to perform my “civic dooty” today so I’m going in for jury duty. No telling where I’ll be at the end of the day.

Anyway, Space Weather News had a neat project that may interest those gathered here – how to construct your own backyard magnetometer for detecting solar flare impacts and such.

https://spaceweather.com/images2022/04jul22/MagnetometerProject.pdf

The maker is in the UK and I’m assuming all the parts are available over here.

Jury duty gives the State a cover to invade your privacy, gaslight you, or even stir up gang stalking against mostly law-abiding citizens. Court houses are dangerous places for free men to be in. Be wary.

Got myself all gussied up, got to the court house – after checking the website at home to see if the party was still on, it said “yeah, sure, come on in”, got into town, parked 300 yards away, walked to the grand courthouse and up the steps and the two deputies in the court house said my group was cancelled. We were the last group they had for this month as all the others had been cancelled, too. I guess the guy plead out or something.

So then I had to figure out what the heck to do with the rest of the day. My truck is in the doctor’s office with a hemorrhage and needing a few joints replaced. It still had the tractor key in it (I swear I’m going to replace that key switch on the tractor with a button. Keeping up with that one key has been a bear over the years) along with the rest of my life I keep in it. Anything I leave in the truck in these repair times I always wind up needing. Luckily the mechanic had it out taking a first look at it so getting what I needed was no problem. So I went to the ranch and got to use the tractor for a while doing some clean up taking dead goats to the bone pile so they don’t stink up the corral area any more plus a little bit of road work after the rains so the day wasn’t a total loss.

Nothing like The Man reaching in to remind you your life really isn’t your own.

Every time…

I have only made it to the inside of the courtroom one time, in all the times I’ve been called. Even that time, the dude pled out before we could go through the interview & swearing in process.

I also disgusted!!!!!

they ruined my favorite show…

Naked and Afraid.. its no longer about learning to Adapt and overcoming the struggles of surviving in an unfamiliar environment.. but NOW its who can demonstrate the best Sociopathic personality traits is the winner..

my great great great grandpa.. up until the present generation was seen as the biggest black sheep member of our family.. the older relatives didn’t even want to claim him as family.. the story I heard from a great great uncle was he sent everyone out to gather berries for pies.. while they were gone he gathered up his gear and left them.. no provisions just gone.. now who was heralded as a hero was Daniel Boone ..he heard what he had done and came to their neck of the woods and taught them how to survive.. gathered up provisions to get them through the winter..

if you read the Diaries of the pioneers making their way across the wilderness.. it was about working together..up until the early eighties a community still worked together to solve the issues of the day.. schools had the PTA once a month..

network programming about decency.. today the programming encourages deviant life styles .. children’s games all encourage violence.. mom is hard at work trying to help provide for the family and in the process has taken the adult presence out of the home..

I was really disappointed … at how they changed the programming..