Everyone has a messy shop, to one degree, or another. I’m just more guilty than most because of my youth.

See, my Main Hobby was ham radio. When you work on a radio, you do whatever repairs and adjustments are needed. Then seamlessly slide into playing with it. There’s no logical “break in the action” to pause and clean up. If anything, there’s a certain “magic” to a piece of tube radio gear with the scent of fresh rosin core solder wafting in the air…No disorganization penalties.

Breakthrough!

This week, staring at a several months-long accumulation on the main workbench leftovers, it occurred to me the Cleaning Project simply looked too overwhelming to even begin.

I’m an ADHD kinda guy. Like to get in, get done, get on to next. But THIS was a God-awful pile. A foot or two high in places, the usual “head down and just fix it one-item at a time” sent me into a panic.

So, I thought about it. “What’s the matter with You, Ure?”

Too confusing? Too complex? To…overwhelming?

Yes. That was it.

Insert a flash from the past: A CEO of a company I once worked for (guy’s name was Bill Brock) gave me two of the greatest personal organization secrets ever. I’d merely forgotten.

“Now, when you do a walk-through of one of our facilities, pay attention to how NEAT the place looks. No cardboard boxes on the floor. If there need to be boxes, are they on shelves? Same with desks. Are they messy with papers scattered all over? Or, is there an organized inbox, outbox, and enough space clear to work on a report with supporting documents and not have it look like a land fill? Senior managers should at least keep things filed-by-pile….Go over anything noted in the exit interview…”

Then it sank in. File first by pile.

Within a minute of staring at the mess, I could make out a very simple outline of what my “piles” would have to be:

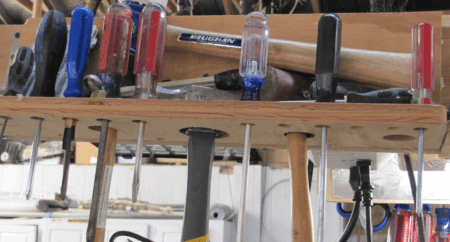

- Lots of tools never got put back. Partly because not everything had a home. A new set of screwdrivers, for example, was still in the plastic clamshell waiting to be unwrapped. But, where would they live?

- There were supplies that had landed (even some mail in there, too). Amazon had gotten things as far as my bench, but I had not put the supplies in the “project piles.”

- “Project Piles” were indistinct. This little do-dad here, would go with a project over in the greenhouse.

- And empty envelopes and small boxes awaited the burn barrel. But, it had been either too dry, windy, phone calls and emails intruded, or it was dark, or…(list of excuses here).

- After all this, a sweep would polish it off.

Easy solution: Put all the TOOLS on one flat surface (the table saw). Put the BURN TRASH on a bench (so I would stand until done). SUPPLIES went on top of the new roll-around chest, (so I couldn’t get to those tools until the supplies were put away.”

The mental fog began to clear. The “cleaning questions” became simple.

Simple Questions, Quick Work

Most of the tool locations were already set. Sharps (knives, blades, razors, small saws, X-actos, and such live in one roll-around. Twist-with-wrist (sockets and wrenches) live in another. Squeeze-to-please (*pliers, diagonals, tin snips and so forth) went in another. This wasn’t too hard to dispense with in a few moinutes.

Still, the new set of screwdrivers didn’t have a home and it’s while contemplating the question “Where should these live, and how?” that it sank in that cleaning was really nothing more than FOUR projects, not just one. The Reductionist Ure breathed a sigh of relief.

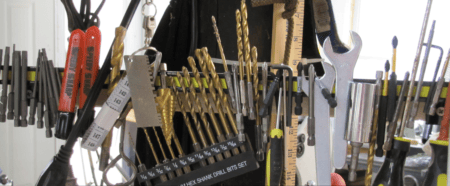

Although not cheap, these 18-inch magnetic strips have been around for years. Thing is, I’d never before been in the position where the old style storage – made of a few cents of scrap wood and some drill press time – would not fill the bill.

If you’re young, this is one of those things where – from the 73-year vantage point – it’s better to spend $17-dollars and 3 minutes to solve a problem than a half-hour (or longer) cutting, doing layout, drilling, gluing and nailing, and eventually mounting the old-style holders.

And there are just some things – like drills, Torx drives, assorted impact drivers, where nothing is as good as a strip.

Like they need another selling point? Magnetic strips don’t collect as much dust, either.

Dear Harbor Freight

“I recently decided to expand to a second mobile tool rack which can be wheeled around the shop to whatever bench has caught my eye for the day. Got one of those General Tool roll-arounds. OK unit.

But here’s the thing: The plastic “insert” ya’ll use is pure shit. The gentlest tug and it rips. Observe:

Honest, it had moved when I slammed the drawer shut and I made the mistake of pulling – not Goliath-hard – more like old man wimp hard – and it tore. See arrow (above).

Thank you in advance,

The Texas Tool Slut Chapter.

Whee! Saw Project

Back during the Covid lockdowns I was keeping a sharp eye on the Craigslist ads because I have always wanted a radial arm saw. As luck would have it, I found one for $50-bucks just up the road a short piece in Brownsboro, Texas.

After being “seasoned” on the shop floor for a year, or so, it was time to raise it from the floor to the workbench it would sit on.

I got out an assortment of one gallon and five-gallon paint cans and proceeded to lift one side (about 60-pounds a side) up a foot, kick in a can, and then repeat on the other side where this time my stack was two cans high. Then three. With Elaine coming by to push the last stack under, I was able to slide it off and into position on a bench.

If you look closely, you’ll see there’s only one bolt holding on the vertical pillar of the beast. But that’s OK because I’ll be doing a ground-up set-up of this according to two books on point. One is “Craftsman Radial-Arm Saws: Wood, Plastic and Metalworking Know-How” – 102 pages worth and dated from 1967.

The other book? A little heftier price-wise: Fine Tuning Your Radial Arm Saw Paperback – December 31, 1899. Which we think might be an error. At $219 for the paperback, I didn’t just write PDFDrive.com did I?

“Have Ure lost your mind?”

OK…there is a backstory here.

When growing up on Beacon Hill in Seattle, we used to walk through the industrial area about 3-miles dodging by-God steam trains at the time, to pick up mail-order tools Pappy ordered from Sears down on Utah Avenue South. (Jeff Bezos borrowed heavily on the Sears business model (right down to the Wish Book at Christmas. Howie Shultz ended up in the building, though).

On the first floor by the escalators up to the pick-up room on the second floor, there were always two demonstrators hawking something, or other. This one time, there was a radial arm saw demonstration. The salesman had a 2-foot wide by 14-inch deep hunk of 3/4-inch plywood.

With a dado blade inserted, he ran conventional dados on one side (saw uncle John do that, so nothing new to the kid here). BUT then he did the opposing face dados with the saw tilted at 45-degrees. The effect was dozens of finely crafted pyramids dadoed into the plywood. “By God, some day, I’m going to build that design into something – furniture or a house feature of some kind,” I swore.

Like I said, my To-Do list for Life has a lot of legacy items I’ve been putting off “until I have time.” But, I do want to get this one done for the Life Review Process game film. (The one many people have at Death where their “Life Flashes” before their eyes. Need this radial saw closure part for my “film shoot.”

New Tool

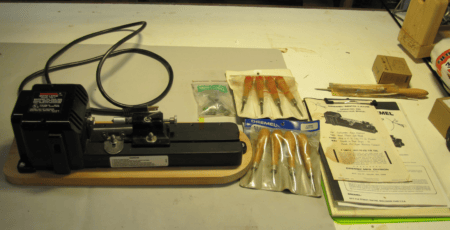

Yet another hundred-dollar marvel has shown up: Early Dremel wood lathe!

Came complete with some of the basic tooling, too!

Other Upcoming Projects

Planning a re-do of the metal working area. Which includes the big lathe, the Taig mini lathe (yes, the Dremel is redundant, but I’ll explain in a sec.) and the vertical milling machine.

I would like to get the Taig AND the metal cutting saw on the floor up on a new *(bigger is better) work surface. Then the other space hog, the metal cutting band saw, could live under as a pull-out.

The existing bench is nothing more than an old bed frame I cut down and welded up to hold a couple of 18-inch-square concrete pavers. 15-years back.

Not sure where the scrap metal bucket (small, ferrous) will live. But outside the shop about 250 pounds of mostly 6061 T6 scrap kindly donated years back by my friend Jim Lewis at eMachineshop.com has provided a nearly limitless source of “creative solutions to many projects.

This is flexing the mental muscles a bit.

One other project which is likely to get done this weekend is putting in some smart switches so Alexa can turn on the central shop vac. Not sure how the turn off will work with the vac noise, but all in the name of science…

Off to pencil out a “mini tools” workstation for the Dremel collection. And water the food supply. Have a great weekend and feel free to toss in comments by clicking down below here somewhere.

Write when you get rich,

George@ure.net

Is that the saw you dropped out of the back of the truck bringing it home? If so glad it didn’t get banged up.

I use mine a lot more than the table saw just remember to do a finger count before and after work.

Yep, that’s the one with a little ball peening… can’t even see it except for a little bend here and there which will be fixed in the detail out and rebuild…

Yes, a radial arm saw is a handy dandy do-it-all tool that does everything to an OK level. Not an exceptionally accurate level, but OK. It can make accurate cuts, but it can also charge you like a pissed-off rhino. Especially if crosscutting with a dado stack. Those extra blades give it a lot of surface area to grab to launch itself at you. If you start that dado cut with a relaxed arm, you will be in for a rude awakening. Stiff arm that sucker like it was a tackler coming after you.

You’ll need 8′ (more or less depending on the length of boards you’ll be cutting) open table top to either side of the saw. I built slotted tables on both sides so sawdust would fall through instead of building up. An extended fence is also handy, so I added that to the tables.

Thank you! Great reminders and ideas.

I got an “eight-footitis” problem: My chop saw needs 16 feet (8 either side of center), same with the resaw bandsaw.

Ditto both the big and small table saws and now toss in the shaper. Now, where to put the big bench in all this with 2 pole building supports to plan around…shesh – head hurts just thinking about it.

Picture a table, 18-20 feet long and 32 inches wide.

Picture cutouts in the table, where a radial-arm saw, chop-saw, heck, maybe even a router table or site-sized table saw can be set on sub-platforms, so that all top surfaces are planar. Add two roller-supports. You can now make the board for Panama to do that “old work” repair, without working up a sweat: Rip that 24′ rafter to its proper width and make the compound mitre cut where a previous builder wanted to show off his trig skills, etc…

Could you put on locking casters that allow the saws to be moved in and out of a single open spot in Ure shop mayhem, or maybe pushed outside?

Yes – but there is a big butt here…more in next weekend’s report

“Yet another hundred-dollar marvel has shown up: Early Dremel wood lathe!”

at one time I had four lathes.. one that came from the school another that came from a factory when they shut down and the guy died his wife gave it to me.. a legacy mill… the one I had was not computerized.. but the same thing..

https://youtu.be/WTxRBQhaYRU

and a small hobby lathe.. I have gotten rid of all of them except the mini lathe.. which I use to turn down pens and pencils..

https://youtu.be/Oq4VhV5YEjU

https://www.pennstateind.com/store/pen-kits.html?gclid=EAIaIQobChMIqOX1hu7U9gIV7R-tBh0X_QFtEAAYASAAEgKUaPD_BwE

I have an extension table for it to.. but have never taken it out of the box..

I married the wrong man. I should have married the guy who knew how to sodder or the guy who became a wood shop teacher. Hahaha. I have paid a fortune over the years to have things fixed.

Get a few tools, Eleanor! It ain’t that hard to learn, or people me would not be able to do it.

You know, I’ve said this a lot over the years: Teaching is more about letting people “make supervised mistakes” – from which they will take the lessons they will. The role here on ShopTalk Sunday is to give people their self-confidence back in order to expand their personal capabilities and boundaries.

Take today? Got a mission on the roof to check things out before 2″ of rain tomorrow, replanting some new frost-hardy gardenias, will get a couple of tubs of bean sprouts going, plus finish the rebuild of the old swamp cooler and build and enclosure for that. Then, will start working on the air handler for that (a bug screen and an air filter holder for the MERV8 filter for the garden room. If there is any time left over before having my drinks and wine while cooking, I will work on putting an “engineered flooring” top of one of the benches in the shop.

But, seriously, Sunset’s Home Repair Handbook https://amzn.to/34WOyRf or their Basic Carepentry book *Used https://amzn.to/3tnqArU will get you a long ways. More important is have the right tools.

I do a lot of “making” including wood, metal, 3D printing, small and micro projects, and advanced electronics. So each one of theses “has its place.”

But reading a few good books (did I just write PDFDrive.com?) to get you some baseline knowledge, and then a good tool kit.

Low end, you might roll with a WorkPro kit like this one for $130 https://amzn.to/3IpyogU But most of the under $50 “tool kits” are pretty marginal performers and might want to avoid them. A lot less douygh ($80) this ProStormer kit looks OK and gets great reviews, too: https://amzn.to/3trAhFP %10-bucks cheaper at $70 is HiSpec’s https://amzn.to/3ijTjrl

On the upper end of things? Electronics tool kits are nice. Without asking me (or Hank in Hawaii what to put in the case) Jensen makes a good electronics kit for a little more money (Actually, over $1,000!) https://amzn.to/34WKl03 If you decide to learn electronics, the book How to Diagnose and Fix Anything Electronic https://amzn.to/3qogrcr is pure gold. Spoiler alert: Capacitors are the most frequent failures, anything that moves (rotary knobs like potentiometers) fail and Resistors overheat and values go off the chart.

More than anything, though, it’s a matter of choice: Do I have the time and inclination to go learn something and do skill building? Or, is the best use of my time to keep doing what I do professionally and then write checks.

Personal call, dear. I just like the “self reliance” rush that comes with being a do everything (fly my own plane, sail my own boat, build my own house) myself.

YMMV

Yes the feeling of satisfaction of doing it all, or mostly all, yourself is great. The past 3 days was working cattle and thankfully I had the Executive Committee to help along with the prettiest vet you will ever see. I suspect she was a primary factor the volunteering of the Committee. She also stapled and bandaged a finger pinched in the squeeze chute… no charge. The Executive Committee met at the local cafe after church and we passed around a bottle of Ibuprofen and way too much coffee then discussed who was up next. Holy crap tommorrow?!!

But no kidding even after 3 days with my arm inserted up to the armpit I won’t say where times 120 head I wouldn’t be anywhere else in the world.

I still have the mostly empty shell of my Jensen toolkit from work. Dunno why. During working years it was stuffed with custom tools and parts for repairing video and audio connectors, cables, and odd equipment that I might need out in the field. It was a heavy ‘arm stretcher’. Most has been redistributed to the home shop now, and I don’t do field work anymore. Gotta get rid of that case now.

I generally agree with George, with one extra caution: If you(or anyone) has long hair, put it up and cover it when working with any power tool! Read up on shop safety and make it religious until you’ve got some shop time under your belt. Even then, good practices can enhance longevity, for both yourself and all your body parts. That said, have fun and build confidence!

BTW, I love long hair, but not loose around machinery of any kind.

NO DANGLES near ROTATING EQUIPMENT! A grade school friend of mine lost his father that way. Was working on a christmas tree lot in the woods with an old arbor driven table saw. He had a long kerchief around his neck that dangled into the rotating shaft and pulled him in. Very sad.

https://warnews247.gr/prasino-fos-apo-ton-rosiko-lao-ston-v-poutin-min-distaseis-kane-chrisi-pyrinikon-oplon-an-krithei-anagkaio/

https://sgs.princeton.edu/the-lab/plan-a

Hmm… makes me think they should have taken steps to de-escalate all of this mess when they had the chance to.

https://twitter.com/Angelo4justice3/status/1505151044858359810?ref_src=twsrc%5Etfw%7Ctwcamp%5Etweetembed%7Ctwterm%5E1505151044858359810%7Ctwgr%5E%7Ctwcon%5Es1_&ref_url=https%3A%2F%2Fwarnews247.gr%2Ftexas-fytepste-sfaira-sto-kefali-tou-poutin-chamos-se-dimotiko-symvoulio%2F

Is this Another Democratic candidate for President…

Why can’t we get any decent people to run for president.. and now will we have an election in 24… seems to me like all the F@@king morons are coming out of the political woodworks..

Think that’s some form of psychological warfare.

Cause we have NO choices, they pick em YEARS AHEAD of time, except, for Trump, he was an outlier.

All they want you to think of is YOUR TEAM; ARE YOU RED OR BLUE – BABY???

Heard of WEF?

Mr. Prime Minister Boris Johnson, Teresa May, Angela Merkel, Mr. FK Up Frenchie, ALL OF THEM picked ahead of time…even O’Biden.

He’s a Zionist, too:

https://www.thekashmirmonitor.net/im-a-zionist-heres-a-timeline-of-joe-bidens-blind-love-and-commitment-for-israel/

Ya’ll need to watch George Carlin; he really had it going on.

He knew all about it. Tells you about it, too.

We got Trump, who has withstood several thousand times the investigation of any criminal in U.S. history and come out clean and innocent of wrongdoing, yet there are people who’re so stupid or narrowminded they still believe him guilty of a crime. That “guilty without proof” narrative is so pervasive and has gone on for so long that people who should know better have begun to speak as if Trump committed a crime.

The only crime Trump committed was crashing the uniparty’s party and attempting to upset their cart full of rotten apples.

In two months DJT will have been Federally investigated EVERY DAY for SIX YEARS.

As you have asked a number of times: “Why would anyone subject themselves to this kind of treatment?”

The reason we can’t get decent people to run for high office is because unless they are really dirty, and dirty in a predictable manner, they will be run through the “sex wringer,” the “theft wringer,” the “prejudiced against some group wringer,” etc., and if those don’t dissuade the decent person from running, they’ll be investigated, both by the “press” and now, also by an aggressively antagonistic DOJ.

DJT went through the entire above gauntlet. He’s “racist” even though he hung with the brothers and was in long-term relationships with Black women, or because he singlehandedly broke the race barrier in Palm Beach. He’s misogynistic because he employs more women than men and pays them better. He’s anti-semetic because his daughter and son in-law are Jewish. He’s a dick because he gives away millions of dollars anonymously, instead of claiming credit like a good little leftist.

Yet people believe this garbage.

And you ask why we can’t get decent people?

Really…?

I’ve watched alot of these nuclear exchange scenarios and they seem underestimate damage and fallout casualties.

Everyone should check out Nukemap website, choose your location and the type of warhead. You can see the destruction and fallout drift on the map. Sobering to say the least. 5 to 10 warheads for each of the 30 largest cities and most military bases, nobody will go untouched.

Sorry G for being off topic on a Sunday but the world’s governments have completely lost their minds and the average Joe is gonna be screwed.

Average Joe’s always gets screwed – it’s what government do lately.

The real “underestimate” is they all assume Russia will fire a warning shot and things will escalate in a m/l hyperbolic curve from that point.

I don’t.

I don’t believe, if Mr. Putin is forced into a war with the West, that there will be a warning shot. Putin is a fighter. Biden is talking “hackers.” Russia has nuke-proof stocked bomb shelters for 126mln people and Putin, if he thought about fighting the U.S., would be thinking about surviving Armageddon. He will unload on our known silos & subs, C&C, and pop centers before we finish patting ourselves on the back.

Washington D.C. is 28 seconds away from obsidian…

Mr. Biden is a bully. He doesn’t know how to fight, physically. He knows bluster, threats, then bringing a lot of help along to intimidate others so he’s never had to.

When I was a kid I was in a lot of fights. I could not tolerate bullies or boys who beat up on girls (generally the same bunch.) Teasing’s fine, abuse isn’t! I won SO MANY fights by, when some kid was running his mouth to tell me what he was going to do to me, simply backhanding him in the chops. He and his buddies would run away crying every single time because every bully is a coward. In a stand-up fight, I never swung first. Against a bully, especially when he brought a crowd, you have to hit first, and hard.

If we get into a dust-up with Russia, Mr. Putin will hit first, and hard…

1) Some several years ago I bought 15 rolls of Kester “60-40,” rosin-core solder, three the larger kind, and the rest the very fine gauge kind. It was cheap (and available). Thank God I did. I probably have a lifetime supply. (Now, unobtanium)

2) “Piles.” My wife calls them “piles,” and she hates them. She says they are messy, and need sorting and 95% (or better) discard. No: this is wrong headedness, They are NOT “piles.” They represent a sophisticated and flexible dynamic filing system: They are, “M.M.S

C.O.F.S.S.”

Multi-Modular, Stratified, Chronologically Ordered File & Storage System. This subtle methodology escapes my wife’s simple mind, fixated on the APPEARANCE of “neatness”– an unworthy and essentially impossible and unstable and unattainable condition,

My Stuff isn’t lost in “Piles.” It’s Chronologically Stratified in a Multi-Modular Stratified Manner.

The horrible fact that I can locate any particular thing in a few seconds by means of MMCS methodology drives her bat-shit crazy — and she periodically tests me with no warning to no avail, as I always find the thing being sought very quickly, frustrating her no end.

Neener, neemer, neener…..

“Kester 60-40,”

Years back I heard they were going to eliminate lead based solder, so I stocked up also. Yep… lifetime supply. The new tin-silver stuff is crap for electronics. Doesn’t flow well, requires too much heat.

Yeppers. I honestly preferred Ersin 63/37 multicore, but when “provisions time” came around, I decided that “to solder, one must have solder” and bought a short-case of Kester mixed .031 and .062 off eBay, for a couple bucks a pound.

Stuff’s still there, probably no longer that cheap though…

Silver solder is for jewelry. It’s damn’ near a bronze. I’m not even sure it’s possible to solder components to a PCB with it, without burning the traces off the board, because it runs like 500 degrees hotter than SnPb.

Check low temp solders on Azon:

BOHOOLs 63/37 Rosin Core Solder Wire, Tin Lead Soldering Wire for Electrical Soldering, (0.8mm 100g), Premium Low Melting Point – https://amzn.to/34Y4DX1

Our company is finding that out now days any way

@George

“Check low temp solders on Azon: BOHOOLs 63/37”

$45 a pound ain’t gonna happen. Ersin Multicore (may no longer be British — Loctite bought Ersin) and Kester in either 63/37 or 60/40 are considerably cheaper.

https://www.amazon.com/Kester-24-6337-8800-Activated-Solder-No-Clean/dp/B00068IJOU

…and I just pulled that one off the pile. IME Mouser, Digi-Key, and Newark are all cheaper than Amazon for stuff like radio solder and either solder or crimp connectors…

I have pile-itis, too, and dang it, I can locate anything at any time, it’s quite the elephant memory storage feature peculiar to some humans.

IF the spouse is irritated by this unseemly decorative pile, we have to rearrange them here and there, but it is its own organizational style.

Hubs, his desk is clear and neat and mostly clean (as long as I dust it and wipe it down).

My desk, 25+ more daily details to keep up with, memory banks being used all of the time. I am the keeper of the records/data/detail/etc., so it’s easy to pass all info to me, that’s the secret to his clean desk!

He says he remembers what he needs to; I remember everything, which means I remember everything he has forgotten.

I found three mugs at a garage sale:

One says: A Clean Desk Is The Sign Of An Empty Mind.

I also found: Mr. Right.

And: Mrs. Always Right.

I have noticed that 2 of those mugs have gone missing; can you guess which ones?

Nuff said!!!

We’re with you (sorry gals, you don’t have the imperfections of us guys!).

We’re hard-wired to do as you do. So most of us have a standing project called cleanup.

I’ll get the point.

Ure didn’t say it in so many words so I will.

A place for everything and everything in its place.

Problem is when we finish a project we’re finished with it. We often leave the stuff in the shop with the best of intentions to soon put them in their place.

One project follows another and, … well you know. Now cleanup becomes yet another project.

What do I do? I break it up into numerous small ‘projects’.

First, clear the floor -pipe clamps, etc. Then any electric tools. Then any of the flat surfaces -benches, table saw, etc.

Then, then, almost everytime I go into the shop, I go to one of the ‘table top’s and put away an item or two or three.

It doesn’t take lone before the shop begins to look better and items are easy to locate.

I also have the same dilemma as Ure with new stuff.

A store had a fire-sale on the best red Milwaukee screwdrivers. Like I really needed them, I couldn’t pass it up! Purchased the largest most complete collection.

However, the place for most screwdrivers is on a pegboard behind a workbench. Buying them meant re-doing the pegboard. Now it becomes a project.

And tossing out some or many of the old but loved and still useful screwdrivers means another useful but unpleasant project. Memories.

Finally, Ure is still in the tool accumulation phase of life. Almost all of my improvement projects have been done. Happily, now it’s occasional maintenance for me.

Which means I am in the dis-accumulation phase of life. I give tools to our kids, at least the those they may want, and try to sell others.

When I have purchased a battery powered tool, I make sure its the same brand my sons have. We can borrow items.

I am learning those coming up behind us are not tuned in or as shop capable as most of us. They didn’t take woodshop or metalshop in school. Or have parents that taught them the trades. Probably like many on this list, my kids could build and wire a house.

So my decades old 12″ almost ‘new’ Craftsman wood lathe and excellent tools has little interest. Perhaps my 10″ Craftsman Contractor Series Radial Arm Saw with DeWalt vacuum might find some interest -but it has to be taken apart and carried up the basement stairs to remove it from the basement shop! A project! :)

This life phase is turning out to be something different than I planned.

“Then seamlessly slide into playing with it.”

Um, I call this “bench-testing.” Sometimes it goes on for weeks, when I have a truly mission-critical piece like an S-38 or S-120…

Or an sx-117,m sx-101, ht-37,/….;

Hi George;

I bought that exact same Sears Radial arm saw back in 1982 with an income tax rebate Cheque from Da Feds [Canadian here].

It’s moved with me to two houses [and wives!] and the number of projects and renos built with it, is numerous and still ongoing!

One of the best things I ever bought.

I still see them at 2nd hand stores for $50 to $100 up here.

Da Retired Guy

See? This is what I’m talkng about – True Makers love making and the tools that allow the craft.

here here!

We love making and the tools that allow the craft, but most of our making is still making buildings, rooms and other space for them and the materials they process!

When I saw Dilbert this morning, I immediately thought of George… Mister “Data Driven”.

https://dilbert.com/strip/2022-03-20

I bought my well-used Monkey Ward radial arm saw in 1972 and got a 4″ jointer thrown in at $150 total. Both have been with me through 3 moves over 175 miles. That saw has built furniture, cabinets, a barn, several decks and numerous smaller projects over the years. Now that I have a small table saw and a miter saw, the radial arm is getting a much-deserved rest. (Time for a rebuild.) The nice thing about the old tools is they were made to be repairable. I’ve replaced the bearings in that old saw several times over the years, and the brushes once.

Wards were Rockwell/Delta Pittsburgh, I believe. My Craftsman (and most others) were Emerson Electric.

All parts are still available. The best thing about the old, rebuildable tools, is they can be had for a tiny fraction of their modern, junk counterparts.

BTW the gun bluing I used on my column is still rust-free…

Pre EPA bluing…hmm…surprised? Nyetski!

Pre-EPA? Naw. AFAICT EPA hasn’t touched this’n.

It’s the basic Birchwood Casey kit which you can still buy:

https://www.amazon.com/Birchwood-Casey-Perma-Liquid-Finishing/dp/B000KKELM8

It still contains 8-9 different acids, is still incredibly dangerous, and I still recommend you use it outside, whilst standing upwind.

https://duckduckgo.com/?q=Birchwood+Casey+Blue+remover+Liquid+msds

https://duckduckgo.com/?q=Birchwood+Casey+Perma+Blue+Liquid+msds

https://duckduckgo.com/?q=Birchwood+Casey+BC-16225+cleaner+msds

George, I decided to try whittling, bought a couple of books, some wood blanks, and a few tools. My hands are deformed but I think I can do this as I whittle down some rims while basket making.

I don’t see me building big projects, but man, those pens made on a lathe really looked cool! I bet I could do that.

Get a pair of carvers gloves – too easy to rip a hand open.

Look into 3d printing as an alternative, lol, or get a dremel tool and holder and carve that way. Much better with suboptimal hands – even mine!

“Get a pair of carvers gloves”

The box stores sell Kevlar garden gloves. They’re more flexible than suede, less than jersey, but nearly as good as chainmail for accident prevention.

I see no mention of the touted ‘Tool Box’ cure that you ordered previously. Apparently that ‘training tool’ was a failure. Yes, “A Place for Everything, and Everything in it’s Place” are words to keep shop by. Next time you have an urge to get a new tool, first find a place for it. Plan ahead.

First time I’ve seen the word “Renaissance” pop up since the Web Bot predictions years ago.

https://oilprice.com/Energy/Energy-General/The-Fossil-Fuel-Renaissance.amp.html

I was expecting something more artsy and colorful but, a revival and renewed interest in things that have been slowed or stopped, or ways we use to do things to get by, might be more appropriate.

Since it’s STS(or Tool Slut Sunday), I’d throw this out to everyone: Does anyone know of a GOOD manual can opener? One that can smoothly open 100,000 cans without a hiccup? I’ve yet to see one. Even the best one I’ve had started to fail after about four years. IMHO, the best most can hope for is 100 years of personal life, so that should be a reasonable design target, at least. I figure 100,000 is likely at between two and three cans/day on average. I don’t like the side opening units since they leave a very sharp edge on the can. Just the normal ones that can open a can cleanly after 100K cycles. That, one spare, and a couple of 100 year toasters should fit out a kitchen, along with a cast iron pot or two.

You might have better luck with less “can-can” and more grow-grow?

I do believe that there’s an appropriate balance. I spent a lot of time and money trying to grow grow something that was edible without even a bean to show for it. Lots of water into the ground, manure, tilling, seeding, etc. I figured that eventually I’d have something to show for it. So far, nothing but weeds. My new approach will be more protected and less ambitious. I have seeds on order, FWIW. These have actually shipped, unlike last year when I had to cancel an order that lived in fantasy land. I have been doing OK growing cactuses – they’ve been with me for years and I water them if I ever remember. They’re in pots and I put them outside for the summers. Regardless, it’s even a bit scary to look at fresh vegetables in a store and wonder what to do with them. At least cans don’t require refrigeration and the critters can’t reach them. They’re also everyday food, so there’s no question as to if I can adapt to them. I’ll be making one more attempt to actually grow something from heirloom seeds this year. We’ll see.

Mike , might I suggest the old military issue P-38 can opener, MILSPEC lasts forever, cheap as dirt. Have a couple around here somewhere….

Thanks. I’ll be getting a few. No harm in excess as long as there’s a place for them.

There’s always the commercial kitchen versions that mount to the counter top. Thinking of the type used in a school cafeteria and goes through #10 cans all day…

“Does anyone know of a GOOD manual can opener? One that can smoothly open 100,000 cans without a hiccup? ”

Yes…

https://www.amazon.com/Swing-Way-6090-Crank-Opener/dp/B001CD77VO

I will explain more on the swing away below.. but if you want a no fail can opener .. then get a P-38 I have had one for over fifty years on my keychain.. love it..

https://www.armysurplusworld.com/p38-can-opener?gclid=EAIaIQobChMI_7Ol46fX9gIVFGxvBB01Qw13EAQYASABEgIjlfD_BwE

Now the swing away.. my guess is you are using it the traditional way by cutting through the top.. that use to be the fool proof way to do a can.. BUT…. as we outsourced cans.. to keep prices of products competitive and cheap.. the thickness of the cans decreased as well.. it saves weight and raw resources.. by reducing the thickness of the metal.. they could get an extra quarter can and make a twenty five percent increase in product..

The sides though are still thicker than the top.. because of that.. IF you take your can opener and just flip it to the top so it cuts through the side.. it will never fail.. and save you the fifty cents for a p-38. One issue.. is the sides will be sharp.. ( this is a good thing and a bad thing.. one you could cut your finger.. thats bad.. but.. if you get a reflanging tool.. then you can wash the cans and reuse them by canning again.. )

Here is a video showing someone using a traditional can opener to cut through the side..

https://youtu.be/_KF88Ar5omo

here is a handy flanging tool.. easy to use..

https://www.aircraftspruce.com/catalog/topages/flanging360.php

If you decide you want to can your own and reuse the can’s.. then here is where I shop..

https://wellscan.ca/product-category/metal-food-beverage-cans/

the alaskan extension office has all that you need to know and videos to support the material for canning in can’s at home.. no need to buy a book.. although if you are interested I do have some favorite books on the subject..

Carp that is smoked..( the way I like it.. ) brined and canned in oil tastes just like kipper snacks.. carp or white fish deboned and canned in olive oil tastes like tuna..

https://youtu.be/0kM5FInS4lg

Amazon has a good article comparing manual can openers:

https://www.amazon.com/ospublishing/story/168e67ac-b7ec-4cc3-a0e0-3bf2142bd0fd/ref=sxin_25?cv_ct_pg=search&cv_ct_wn=osp-single-source-earns-comm&linkCode=oas&cv_ct_id=amzn1.osa.168e67ac-b7ec-4cc3-a0e0-3bf2142bd0fd.ATVPDKIKX0DER.en_US&asc_contentid=amzn1.osa.168e67ac-b7ec-4cc3-a0e0-3bf2142bd0fd.ATVPDKIKX0DER.en_US&cv_ct_we=article-page&qid=1647873854&ascsubtag=amzn1.osa.168e67ac-b7ec-4cc3-a0e0-3bf2142bd0fd.ATVPDKIKX0DER.en_US&pf_rd_p=5846ecd6-3f37-4a28-8efc-9c817c03dbe9&pf_rd_r=KK8NRK201Z5ZF3AES863&pd_rd_wg=fi4ob&pd_rd_w=J44xO&tag=reviewedoap-20&asc_contenttype=article&pd_rd_r=d05ac304-7a29-4ab9-a81a-04ad10aecacd&cv_ct_cx=military+can+opener

The military can openers (P-38 and P-51) will probably last forever, but look hard to use. They’re also very small and could be easily lost, which may be why they’re usually sold in bundles. I have a few for prepping and hope I never have to use them.

I have two Swing-Aways that have become almost unusable, so I bought a Kuhn-Rikon LidLifter Can Opener, which is easy on the hands and I like better than any I’ve ever had, but it may not last as long as all-metal ones. Since preppers need duplicates, I’m about to order the EZ-DUZ-IT that Amazon rated “Best Overall.” One of its main attributes is durability.

“(P-38 and P-51) will probably last forever, but look hard to use. ”

Not at all @Tumbleweed…the little notch hooks on the flat felled seam of the top of the can and the hook goes through the top.. then you walk it around.. https://youtu.be/1jnQbN_2Tnk

you’ll find you will use it as a screw driver more than a can opener.. but I have opened at least a thousand cans with it..

I have never tried to reflange a beer can.. it is something I want to do.. but the aluminum is so thin I get concerned that I will bend it up..

https://youtu.be/2y15Dr_6m9A

https://youtu.be/rlUth-Lt474

I guess I could have shared this flanger.. but I have the hand one.. works great.. twice around will give me the small flange needed.. I did use an empty can to get the right angles on it..

https://www.ramsmachinery.com/store/p2/RAMS-2002_20ga_Hand_Flanger.html

Great answers! Thanks to all! I looked at the reviews on Amazon for EZ-DUZ-IT and they’re mixed. It seems that someone did a cost reduction redesign or just outsourced to another vendor, but there seem to be two somewhat different openers with the same name and they’re all in the same bin at Amazon. One is great and one is just OK.

LOOB, great information on flangers, perhaps it will help when I build a seriously underweight vehicle of some sort – preferably Part 103 or a hypermiling road warrior thing. I just can’t see spending $725 to flange a can! That said, the results do look good. The third flanger in the video looks like something that could be easily modeled and 3D printed in any size. Of course, that design will work for a hole, but not for a can.

Ah, another one of those topics I researched extensively 10-20 years ago (and prices will reflect this disparity…)

The best can opener in the world is the Edlund or Dazey series of commercial can openers. (Dazey is long-gone but one still shows up once in a while.) These are the ones which bench-mount and will open anything from a #10 to a 6oz Contadina Tomato Paste can flawlessly, and are designed to open 100 cans a day, for hundreds of years. Prices start at about $369 and go to well north of $1000, for a manual can opener, with a 2″ knob on its crank. Every part of these can openers is replaceable, including the knives (BTW Edlund and Dazey knives are interchangeable), which is why they’ll last forever. The can openers could be scarfed off eBay for between $40-$50, sometimes less, if one were a patient shopper.

The absolute best “home” can opener is the “Speedo,” made in the 1920s and ’30s by Central States Manufacturing Company. It is the only home can opener I’ve found which will open any can, consistently. Good luck finding one that’s serviceable, for under a hundred bucks, or not in a museum.

Now, the reason I started down several paths, the threads of which now permeate my writings now, trace back the the Swing-Away can opener.

When I bought my house, it came with a 1940s or ’50s vintage Swing-Away can opener. It worked splendidly, but being a dumbassed kid with a wife who liked automatic gadgetry, I chucked it in a box and replaced it with a series of electric can openers — all of which shit themselves within a couple months of their warranty expirys. Along about 2005 I remembered how that old Swing-Away “just worked,” so I went out and bought a nice, shiny new one.

Within two months, the teeth were gone off the feed cog and I had twice bent the top lever, piercing can lids. I thought “This thing is serious junk.” I bought another, with similar results, then went out to the garage and dug out the original — flawless!

Swing-Away was a family owned & run company whose owner retired or passed away, and the company was sold to a Chinese conglomerate. Swing-Away can openers made since about 2001 are Chinese, using Chinese steel and Chinese fitment tolerances. They still carry the same reputation the family built, especially amongst the RV industry and community, but they’re as much junk as anything else Chinese that’s manufactured for home use.

My 70+ year old Swing-Away is the can opener I use every day. My 100yo Speedo is the can opener I use elsewhere (it’s better than the Swing-Away, but not by much, and it’s a bona fide antique) or when I get a #10 that the Swing-Away can’t handle. I own one Edlund, two Dazeys, and an extra set of blades for each. I don’t have a food prep bench, so they are in EOTW storage…

…And yes, I may have bought 20 different manual can openers and done a hands-on eval. ‘Thing is, I was (I thought) past writing on the Internet, so it never occurred to me to evaluate these can openers on-cam and do a writeup. (Know anybody who wants a “like-new,” 50-80yo Dazey or Ecko (or similar) home manual can opener? I probably have a few left…)

FWIW my Edlund came from a chain pizza joint. It got dull, so they threw it away (new blades, 2-pack, reversible were less than $12, and to someone who’s sharpened chisels, they look resharpenable.) People under 40 can be really dumb…

* EKCO *

New tools alright . Even this Ukraine show is starting to sark . Very moon landing , 911,Covid like production . Insertion valid in USSA

Not those kinda tools, Len. Jeez…what language do yas’ll think in down there?

No one thinks like me. Especially in this sewer of jabbed down here . I thrive on isolation makes me tougher . Cat(20 yo) wife and fitness . This ones to the end . I got no plans on second place

I’m a big fan of perforated angle iron for screwdrivers. I’ll double it up into a “U” and it keeps them from being wobbly. Bore out a few holes for the fat ones and grommets for the smaller ones. Just finished a 10 hour rebuild of the long neglected mower deck, one of those commercial jobs.

Replaced every bushing & bearing, straightened and welded whatever was bent or cracked. Slathered on a few coats of Krylon Banner Red. Went from a deafening roar to nearly silent.

Pictures!

https://m.media-amazon.com/images/I/6170gdhKGwL._AC_SY355_.jpg

“I’m a big fan of perforated angle iron for screwdrivers.”

I prefer a 2×3 with half-inch CPVC for the screwdriver shaft housings. I cut the pipe with a tubing cutter and trim each pipe so the bottom ~1½” of the driver is hanging out, as a confirmation that the driver in each hole is the one that’s supposed to be there. I’ve done wire and rack (the old screwdriver racks which actually look like Scott’s angle iron, only thinner) and prefer the wood + plastic. It’s fast, cheap, clean, quiet, and elegant.

This years grammys . Best picture Ukraine. Best actor Vladimir Putin best supporting actor joe Biden best screenplay Ukraine best cinematography Ukraine best special effects Ukraine. A mention for best foreign film . China directed by Xi ping

That was pretty good, Len. Best comedy: Congress. Etc.

Comrades,

Such a treat on a peaceful Sunday evening to put the feet up on the coffee table while watching a fairytale unfold on the airwaves.

Stepan the Cat (not Stepan Banderos) and his human Anna, recent TikTok sensations, have escaped their Karkhiv Ukraine bomb shelter. None other than the head of The World Influencers and Bloggers Association, Ms. Maria Grahzhina-Chaplin of Monaco, brings the happy-ending news that Stepan and family are safe and sound somewhere in France. While Ms. Grahzhina-Chaplin may not be a household name amongst us commoners, she did ascend to a Miss Ukraine 2002 in Lviv. Her cv includes Russian television programming as well as an assistant stint in the Russian Duma. Her father was the famous Soviet radio engineer, Anatoli Chaplin, unmentioned in English Wikipedia. Sadly an ordained sibling to Maria, described as the “right hand of the Patriarch”, passed away two years ago from a heart attack while on a bench at Moscow’s Church of Theodore the Studite at Nikitsky Gate according to “Arab News Service”. Nikitsky Gate was the site of troop clashes with Bolsheviks during the Russian Revolution. St. Theodore the Studite was a 9th century Byzantine monk who opposed the emperor and lost. It would appear the recent decedent had a falling out with the president as well as publicly stating the Patriarch “did not have much time left” before encountering his own demise.

Even Ackerman has given up good . Grow horns and sark schwab all of yous . Sheila’s wooses facist sympathise crawlers. Don’t worry you got the moose guiding you hard

Here’s an economic irony: The people who are $30 Trillion in debt are giving YOU a credit score!

Good one, Hank!

You all beleive this sheet from the moose and his mates ? Get a Farken life and take your jabs

Please excuse this late Off Topic comment:

Pleading for a toaster that will toast

Both sides of a piece of bread

Amazon lists “hundreds” have bought four

I am 76 and just want a nice piece of toast!!!

Thank you, Montana Mike

ps: have you tried a “P51” military style opener??

https://www.ebay.com/itm/255448331691

https://www.ebay.com/itm/275221372575

https://www.ebay.com/itm/185348017500

https://www.ebay.com/itm/185340730090

“Sold” prices for “working” Sunbeam Radiant toasters seem to run from about $70 to about $300.

https://www.ebay.com/sch/i.html?_from=R40&_nkw=sunbeam+toaster&_sacat=13905&LH_TitleDesc=0&LH_PrefLoc=3&rt=nc&LH_Sold=1&LH_Complete=1

Not purchasing advice:

I do not recommend a person check out anything later than the T-35 (late 1950s.) The T-40s came after the ascension of the beancounters, and the AT-W series (there’s a lot of different AT-Ws. You could buy them new in the top shelf department stores as late as 2010) were $200+, and junk.

The T-20 or 20a is the true “100 year toaster.” Mine is 72 years old and will toast completely properly, slice after slice, whether you’re making a melted, toasted peanut butter sandwich or toasting two loaves to dice, to make homemade stuffing.

The only caveat to the old toasters is they were made to toast bread — conventional 5x5x9/16″ sliced bread, so they will not accept 5/4″ thick slices of “Texas Toast.”

Again, not purchasing advice — merely my anecdotal experience…