TL;DR: Sharpening is one of those simple-but-deep shop skills that separate hacks from craftsmen. Everything you build boils down to four riffs — measure, cut, join, finish — and cutting only works when the tool’s sharp. Angles matter, whether it’s 15° on a sushi knife or 30° on an axe. Grinders and belts speed the work but can burn the temper if you’re careless, while chainsaw and round-blade sharpeners each have their place. A well-stocked “sharps drawer” keeps stones, files, and guides handy, because sharp tools are safer, cleaner, and faster. There’s still a side hustle in knife and saw sharpening — restaurants, tree crews, woodworkers — and the old Foley-Belsaw rigs on eBay remind us that keeping edges tuned was once a trade in itself.

Building the “Sharp Shop”

Orientation – always good on the first day of class, eh? To all be on the same page here, let me lay out the “mental indexing” of my shop and how I go about building (sometimes) really good designs – out of my head – on the fly.

First is to understand in DIY – or even licensed tradesman work – including new construction and remodeling – there are only variations (riffs, musically) on four simple ideas.

- Measure and Mark: You’d think this was basic but no – I have seen total screw ups because people got in a hurry and didn’t measure right. (Measuring is also the First Principle of Electronics – we will start on that free fall school next week…)

- Second is Cutting. And this is where we get into today’s topic. In most uses, power and hand tools are best if used as sharp as you can make them.

- Assemble, Join. We do a lot of clamping. No Parkinson’s yet – but I learned (must have been around 60, or so) 15 years back – that without a “helper” to hold things, clamps and jigs were my friends.

- Last step? Finish: this is where the sanders, paint, varnish and plastic fumes start to roll. Yum.

Somewhere, along in here, Elaine would raise her hand (she doesn’t read my columns) and say “You left out Cleanup, Tool Maintenance and Resupply…” Which is why her house is a bit neater than my shop… Somehow, I believe this is common…an actual gender difference?

This will be a collection of columns over coming months that will give you ideas whether you’re a grizzled professional or just a “thinking about it” future DIYer.

Welcome to Sharps School Part 1

Sharpening is one of those “simple but deep” ranch shop skills. Folks think it’s just rubbing steel on a stone, but the devil is in the angle and the patience. The goal is always the same: get two planes of metal to meet at as fine a line as possible. That’s your edge. Miss the angle or wobble around and all you’ve got is a polished butter knife. (Save a couple for putty & epoxy work, though!)

For knives, pick your system and stick to it. old-school whetstones work great, especially if you use oil or water to float away filings. Hold a consistent angle — 20 degrees for general kitchen, 15 if you want sushi sharp, 25 if you’re pounding wood with a hunting blade. Consistency beats brute force every time. Light, even strokes, both sides, until you feel a tiny burr form. That burr is the steel folding over, telling you the edge is real. Then you flip, refine, and strop on leather or cardboard to align the micro edge.

If you don’t have a good set of measuring tools, get thee over to your sliding compound miter saw and cut the angles that are most troubling using old hunks of 2-by-4. Measure out angles and then cut and label them for future use. Like so:

I also may have made up 22-, 23- and I think 18-degree guides, too. There’s that organizing problem, right?

In the shop, tool sharpening is about matching the cutter to its job. Chisels and plane irons get a flat bevel, usually 25–30 degrees, polished on stones or sandpaper-on-glass if that’s what you’ve got. Woodworking (double-sided) tape is useful here.

Axes? Sharpen with a file, not a grinder, unless you like soft edges from too much heat. If you are grinding with a machine, do NOT let the metal come up to yellow or blue discoloration. Temper is lost and your edge will be easy to sharpen but won’t last more than a minute. This is why slow-turning, water-bathed wheels are the knife maker’s choice.

The bigger the better. The reason here is simple: A small wheel, say 3″ will give you a quickly rounding blade edge. Again, OK, BUT it won’t wear well. Get up into a 10-inch wheel and now you’ve got something.

Always file in one direction, heel to toe, with the axe head locked down. Power tools can help — bench grinders, belt sanders — but they’re unforgiving. Again, overheat the edge and you burn the temper right out of the steel. Keep a cup of water nearby and dunk often. Some guys like oil but water is easier to clean up and you will always spill in the shop. Always.

Sharp Machines

All those warnings about machines, let’s roll through some:

Every shop has one of those 6- or 8-inch grinders. They like to hide under things until you need them. Mine was sighted cowering here:

Final step for any edge is inspection. Your tools here are red platelets all over, optical, and cardboard or paper. Platelets first…cautiously!

Run your thumb sideways across it — never down the blade — and feel for uniform bite. Fingernails work a little better – if the blade won’t draw easily – and immediately digs in – then it’s getting close.

Paper tests work too: clean slice with no tearing means you did your job. Thicker cardboard will make you feel better (it will cut with a less sharp blade). 20-pound printer paper (you don’t need to try and cut toilet paper) is a good compromise. (Pappy used tissue paper from gifts when testing his “cut plug herring knife…”)

Remember, a sharp tool is safer than a dull one. Dull makes you push harder, slip farther, and bleed faster. So take the time, learn the feel, and in no time you’ll be the guy with the sharp knives at deer camp and the square chisels in the wood shop.

Sharps: Storage and Roughing

Storage first: Every shop of any consequence has a ton of tool storage. And it’s according to the Shop Foreman’s will. Often, it will match his “mental indexing” of work. For example, an Accountant may wish to alphabetize or assign Tool Numbers to each item. Then, with an intricate enough system they will not get much productivity but they will be able to find and bitch about everything. This is also how Accountants work in real life, too.

Others – like my buddy who is the ex Mercedes big city wrench – will have a $16,000 Snap-On with the tools laid out to perfection. He knows his own tool-handling style by heart. So if he knows that certain kind of passenger car or truck – say a Dodge product – is coming in, there’s a “secret Dodge tools: section. The most commonly grabbed? Right at waist level and so forth.

Same thing applies when comes to how your shop is organized for Sharpening things. But the problem is amplified at home. Unlike my neighbor, see, I work across a wide-range of materials. Not just 4,000 pounds of rolling stock on 4-wheels. A lot of things here are grains of sand under the 10″ SMT electronic circuit microscope.

My solution? First are the basics like: Grippies, Twisties, and Screwies (areas where pliers, wrenches and screwdrivers live). And because the shop is not big enough for a devoted tool roll-around for Jig and Sawz-all chests, I generalized most of my “Don’t-cut-yourself tools!” in “The Sharps” drawer.

It may look like a god-awful mess (OK, it is, then…) but if you need an odd jig saw blade, the bottle of Japanese cutting oil (to put the ultimate edge on Japanese saws and lonely Ginsu collections – or you just need that 12-inch long-handle razor scraper to get an old registration tag off the unreachable part of the windshield? This is where you would start.

Now let’s take a typical shop task – like touching up a chisel. From tool retrieval, you could wander over to the small wood and knife parts grinder:

These are also very good for building dollhouses and scale models of housing additions you’re thinking over.

No? Well let’s “finda-grinda!”

The theory is that the plastic wrap will keep dust off the plastic. But since we have Plexus plastic cleaner left from the airplane, who cares, right? Besides the plastic wrap seems to attract sawdust…

Where would this be? Why under the properly signed area of the shop, of course!!!

I know what you’re thinking: “George, that sign would imply that you do general saw sharpening and things like chainsaws…so isn’t that like, oh, FALSE ADVERTISING?”

Exactly! I used that on Elaine. “You know dear, with that sign up in the shop, we could wake up one morning with customers lined up around the block (which is 12.3 miles out here in the woods). So to avoid Lawsuits (!!!) I need to buy more tools.

And yea, verily it was so.

A little something for table saw blade sharpening:

And for the “chainsaw” gang?

Which – don’t mention it – does look slightly used, but it needs to be clamped to a bench top and I have made some progress sorting out the electronics and metalworking parts to get some free benchtop showing again…

If you are a psychiatrist, you should have signed the papers several paragraphs earlier – now you’re in the same boat with the patient! Which is OK because this patient has a Drill Doctor, too! Because I have tons of whats?

Mind you, this is just the main bench collection – the real depth (things like concrete, masonry, and granite/glass drills and the Forstners and the spades are mainly at the drill press station on the east bench.

The Drill Doctor was picked up (small size) on eBay and a few weeks later, the larger one. Great tool and more than a “bit” of fun…Estate sales are your friend (and Prime Days, too) when you are “shopping.”

You know, that sign isn’t entirely a joke. I have enough shit tools to sharpen (we didn’t go through the stones and whets and files yet…) but YES! I have thought about setting up a small cabin down on the corner where people could come in, drop off a saw, and get it sharpened.

Are Saw Sharpening Shops Still a Viable Business?

Knife and saw sharpening was once a staple small-town side hustle. We are not in the middle of the city, but over time, the city will have to come here. Cities are broken.

Back in the day? The milkman and the knife man made their rounds. Today, fewer people repair and more replace, but there’s still money in sharpening. Restaurants pay to keep kitchen knives keen, tree crews need chains sharpened, and woodworkers want their saws tuned. Chisels and gouges. It won’t make you rich, but in the right rural setting, it can be steady pocket money. Plus, it’s a craft people respect, and that reputation travels faster than advertising.

The other set of tools I have been collecting as a “when it all blows up and basics will matter again” option is a rustic wood furniture-making business. God knows, as a tree farm we have the raw materials…

G2 and I have kicked around setting up a custom log cutting operation, too. “Drop off your logs and we will cut them for a fee” kind of thing. Better use than biomassing, don’t you think?

Looking at gas powered sawmills now… HF has some.

Sidebar: Foley-Belsaw

Secrets of the rainy-day eBay tool slut:

Back in the day, Foley-Belsaw was the gold standard for home sharpening setups. Big, cast-iron rigs that could handle circular saw blades, jointer knives, planer knives, and chainsaw teeth. Every small-town sharpener either had one or wanted one. The company ran training programs by mail, teaching thousands how to set up shop in their garage. Foley-Belsaw’s heyday has passed, but their machines still pop up on eBay, usually dusty but serviceable. They’re a reminder of when sharpening was a trade unto itself — and they’re still solid iron if you want to revive the tradition.

You can still find not only Foley-Belsaw tools on eBay, but they also had dandy locksmith tools like key-cutters and such. I have their saw shop business book/course around here somewhere. And I went through their small engine repair course, too. Which is a great fit with a saw shop in a rural area.

On that note, like we say in East Texas, I have to get back to rat-killing now. One of these days it’s going to cool off enough that Elaine will stop believing my “it’s too hot” excuses. For now, I feel the urge to buy another tool coming on…

Solar: Two for the Road

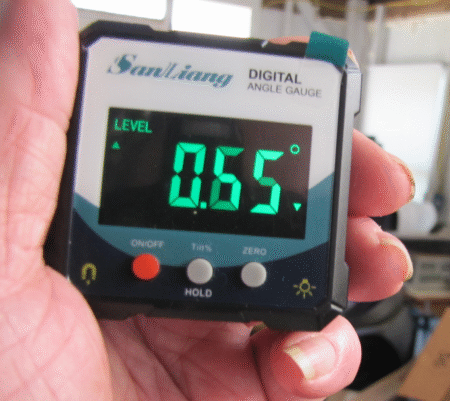

First, is the most common question people seem to ask: How do you know when you are welding up your tee-post and rebar adjustable solar racks, how to figure the right solar angle? Well, that’s easy. Take your latitude (north of equator only) and ADD 15-degrees. Since Palestine, Texas rounds off to 32 degrees, that means our useful winter angle is about 47 degrees. I used 45 being lazy.

Summertime works the other way: Latitude (still 32 unless the crust shifts this winter…) MINUS 15 degrees. I used 18 degrees, not 17 because most mobile homes are 18.2 degree pitched, or thereabouts.

If you wanted to totally optimized in a a mid spring, mid fall setting? Once you have the length for your summer angle supports (which you’ll remember are 1-1/2 in diameter PVC pipe hunks), pick a midpoint between the summer length and the bottom of the lower support bar.

In my case (on one of the arrays) the supports are 45 inches and the lower support is about 30 inches. Midpointing that? 37-1/2 inches but now you’re making more work because you will be adjusting panels 4 times a year, not twice.

Next question seems to be How do you Measure reliably.

Answer: Spend money. $18 minus a penny at the Zon:

You have money? We have tools and seeds (and guns and water and…….oh….loose lips?)

Inquiring Minds Follow-up

How well is our solar working?

And: “What is the everyday carry knife out there in the woods for you, G?”

And: “What is the everyday carry knife out there in the woods for you, G?”

This is called a “Byrd Cara Cara 2 Rescue Lightweight Knife with 3.88″ Stainless Steel Sheepfoot Blade and High Performance Orange FRN Handle – SpyderEdge.”

I go through one of these about every two or three years. Yes, out here is about as tough on knives as it is on lazy people.

Why? It’s one of the few knives that meets all my requirements.

- Foremost is it is a one-hand opening blade. Wet hands or dry, it’s always at the ready. I have a lot of blades to choose from including some almost DELTA/JSOC-USSOCOM/SEAL6/ quality Leatherman products. (Get the extra tools, if you go this route. Maybe start with a LEATHERMAN, Wave+, 18-in-1 Full-Size, Versatile Multi-tool for DIY, Home, Garden, Outdoors or Everyday Carry (EDC), Black $120. Accessorize with LEATHERMAN, Bit Kit, ($31.46) 21 Double-Ended Screwdriver Bits for Multi-Tools and the LEATHERMAN, Bit Driver Extender Add-on Accessory for Multi-Tools, ($27 )

- Second: Serrated edge. Yet, if you are doing surgery, a #10 scalpel plus a cautery knife…but if you need to cut away in free-fall or on a pitching deck in the wet/dark, serrated is the only answer.

- Third: reasonably priced ($42). Spendy enough to be good steel, cheap enough you can take a hammer to it to use as a wedge when you get 4-tons of tree binding on a chainsaw (don’t ask).

Count your fingers before and after your shop visits…especially around knives, power tools, and sharpening gear. You know…the stuff we go to the shop for….

Write when you get rich,

George@Ure.net

Crockery, I say

as I have a couple of crock bowls, that have the right texture and smoothness on the bottom, as I turn the bowl upside down on a kitchen towel/cloth, a little water and sharpen my chefs knife

You missed the part in my book Dr. Between your ears: we ONLY eat on vitreous glass or ceramics like Corelle – because of leachates around acidic foods…and all our best eats have wines or liquors in them. alchemy, right?

just white Corelle, if I recall correctly.

I like my Corella with a blue stripe edge, but mine are mostly straight white also, but a eclectic bunch I own.

Ivy Corelle.

“Restaurants pay to keep kitchen knives keen, tree crews need chains sharpened.”

Restaurants also have commercial meat slicers, such as the Hobart HS6.

“Top-mounted Borazon sharpening system single-action sharpens and hones in 15 seconds and is dishwasher safe.”

Restaurant workers think that vegetable oil also functions as a lubricant, so when the meat carriage gets tedious to push back and forth, they put it on the slide rod mechanism. It works for a little while, then the oil gums up and the carriage seizes. What a bitch it is to clean.

Nobody reads the owners manual.

“Only use food grade mineral oil for lubricating the slide rods.”

Kurobara muich better https://amzn.to/4mXCqlP

“Byrd Cara Cara 2 Rescue Lightweight Knife with 3.88″ Stainless Steel Sheepfoot Blade”

I think you’re missing the point.

(Just kidding! Spyderco serrations have been in my pocket for decades but I do like the point.)

Not to spoil the Sunday, but I’m glad I don’t live in New York anymore.

An elderly couple, living in a nice house with a white picket fence… All of a sudden a savage arrives, tortures and sexually molests them, and then sets them on fire.

“The monster who admitted to killing, molesting and burning an elderly Queens couple was roaming the streets because of a little-known change to the state parole law championed by mayoral candidate Zohran Mamdani.

Jamel McGriff, an ex-con sex offender on parole, failed to register his address this summer — a violation that would have landed him back in the slammer three years ago.

But “Less Is More” parole reforms enacted in 2022 allowed him to stay free.

https://nypost.com/2025/09/14/us-news/nys-parole-reform-law-backed-by-mamdani-allows-85-of-ex-cons-who-commit-new-crimes-to-roam-free/

“Which is why her house is a bit neater than my shop… Somehow, I believe this is common…an actual gender difference?”

Agreed. My wife gave me a small heart-shaped wooden plaque to hang on the wall near my computer inscribed with “A cluttered desk is a sign of genius”. Looking at my garage, my blacksmith shop, and my barn, I must outshine Einstein.

Sales Manager at one TV station I worked at had a desk piled high. On the wall was the plaque: “A clean desk is a sign of a sick mind”.

Great minds …

We have to same go-to pocket knife. I have carried a yellow handled SpyderEdge for over (40) years. I feel positively naked, unsafe, on deck without my trusty safety knife clipped in a pocket edge or bathing suit waistband.

Once, in a long history on deck, there was an impossible over-ride where it was dangerous to sail on with the jammed sheet. I fashioned a hunk of line from my “ya never know” kit to take the load then parted a 3/4″ line with one stroke. Once you go serrated …

ATL: it’s like a morgue here. Not our TomCat mourning … the football fans who stayed up to watch the A&M defeat of homeboys ND was difficult. Lots of people, even kids, will get to go now, through balance of the season. And I now have Saturdays off.

So, there’s that …

Egor

Youse aint kidding, “Once you go serrated …” as OJ learned when he tried his hand at Decapitation, dam near impossible to cut a persons Head all the way off..sinews/muscles/ligaments/bones, with a straight edge Knife.

Nasty video out there of Russian “Orc” officer cutting a terrorists (Chechen) head off in middle of battlefield..those terrorists now fight for Mother Russia in the meatgrindr that is nazi banderras’ folly today.

Thats gotta hurt…https://youtu.be/rgLxt_ca9Ps?si=oy-y1OQITk8Bzuww

Ok..this may sound disgusting but In the slums of Manila, the ultra-poor resort to pagpag—salvaging discarded meat from trash bins, washing it, recooking it, and selling it as food. It’s a heartbreaking ritual born of desperation, where dignity is traded for survival. Yet in today’s world of runaway inflation and looming Weimar-style collapse, even ordinary low-wage earners face a quieter version of this crisis. With shrinking paychecks and rising costs, the ability to repurpose leftovers becomes not just frugal but essential. A rotisserie chicken or beef roast, once a luxury, can be transformed into skinless hotdogs or homemade luncheon meat—ground, seasoned, and bound with potato or oats. These acts of culinary resilience echo the same truth: when systems fail, it’s not the ingredients that matter most but the ability to adapt and overcome… to transform simple leftovers into another meal or two.

2 cups finely chopped or ground leftover chicken or beef roast

1 cup mashed potatoes or cooked rice

1 egg (or 2 tbsp flour/oats as binder)

1 tsp garlic powder

1 tsp smoked paprika

½ tsp black pepper

½ tsp salt

Optional: grated carrot, celery, or herbs for texture and nutrition

Instructions:

Mix all ingredients into a moldable dough.

Shape into hotdog-style logs by hand or using plastic wrap as a mold. or use a sausage stuffer and casings.. cook till the internal temperature reaches 155…. smoke it for a couple of hours .. for skin less dogs immerse in ice water then remove the skins for a skin less dog..

Steam for 15–20 minutes until firm, or pan-sear for a crisp exterior.

Cool and refrigerate or freeze for later use.

recipe 2..

2 cups finely chopped beef or chicken

½ cup cooked lentils or mashed beans (adds body and nutrition)

1 tbsp soy sauce

1 tsp onion powder

1 tsp mustard or vinegar

1 egg or 2 tbsp flour/oats

½ tsp salt, ½ tsp pepper

Optional: gelatin (½ tsp) for firmer texture

same as above..

In a time of looming hardship—whether economic collapse, runaway inflation, or what you aptly call a “time of dispair,” where scarcity and discomfort become daily realities—I through my turbulent times learned that adapting isn’t just a way of survival, it’s stewardship… Depression may whisper defeat, but overcoming it is a radical act of care, a refusal to let despair define the legacy we leave behind. Maintaining quality of life doesn’t mean luxury—it means preserving dignity, ritual, and meaning in the face of decline. By repurposing what we have, teaching through action, and anchoring ourselves in purpose, we transform scarcity into sanctuary. Adaptation becomes a form of resistance, and every act of resilience..True love isn’t found in what someone flaunts—it’s revealed in what they do, especially when no one’s watching. It’s in the quiet acts: repurposing leftovers into nourishing meals, preserving dignity in scarcity, and shaping a shared life where goals, values, and sacrifices intertwine they become one with the other.. in trying to make sure those around them maintain a quality of life…. When you take what others might discard and turn it into sustenance, you’re not just feeding bodies—you’re teaching them what true love is. Because love, at its core, is the ability to see potential where others see waste, and to build quality of life not from excess, but from intention. That’s not romance—it’s legacy… people often see love by attraction physical or in what they have or what they wear.. in reality all of this can be lost in a freak accident or the depth of an economic freefall.. war or pestilence.. by transformation of what your leftovers would be seen as oh no not that again..your repurposing it to give the ones you care about a hand up or show them see adapt and overcome..Its really not as bad as you think..

(“Foley-Belsaw was the gold standard for home sharpening setups. Big, cast-iron rigs that could handle circular saw blades, jointer knives, planer knives, and chainsaw teeth.”)

back in the cabinet shop days.. saw blade sharpening.. Red too thing blades.. I bought the ultimate belsaw outfit and jigs the teeth to replace any size blade..up to twenty inch sawmill..my thought was ten cents a tooth to transform and one dollar and up depending on size of the carbide tooth to be to replaced.it was my retirement income dream..then I was going to make wood toys ..to give away ..or sell where the income from it would be used to give kids with cancer ..wigs ( I gave those away already at locks of love) the cash idea is a child with cancer still wants to show his love for his parents and siblings but because of his hospitalization he’s stuck .let them buy a gift for each.. I would buy a bunch of care bears then put a dinner out gift card for parents..

I still have a few of those little bears around here.. today because of the evil in society you no longer can wander up to the cancer wings..

anyway I got sick and the dream of reds adorning and retoothing industrial saw blades ended..I traded the big saw blade sharpening equipment for stuff needed for the house..the unit was huge and heavy..in its place is where I raised fish.. now it holds freeze dryers ..

https://www.vevor.com/saw-blade-sharpener-c_11021/vevor-circular-saw-blade-sharpener-grinder-370w-3600rpm-with-water-tank-5-wheel-p_010300767190

The vevor is the one I still own.. it will do almost any blade for a circular home saw blade..the one I had that was huge looked a lot like this one but was made by belsaw..

https://www.amazon.com/HQHAOTWU-Woodworking-Swing-head-Sharpening-Intelligent/dp/B0DCVMV7RC/ref=sr_1_21_sspa?

Coool beans Loobsters.

What ya got for Diamond Saw blades ? I use tile cutting saws for Trim Sawing Minerals/Rocks. They are loud as all get out – a dammed painful racket cutting thru hard “Rough” . I recharge my cutting wheels with a Diamond Paste, but got nothing for Diamond Saw blades..nuttin honey.

I just toss out the old an get a new one every year, there that cheap. Only problem is they are only So big, so I have to make 2 or cuts – which really sucks trying line up 2-3 cuts for smooth finished cut line (s).

The “Season” is upon me here in the great North East/MidAtlantic, as temps start to chill, getting Dark earlier and earlier, and my Garage Shop area is so delightfully cool in the evenings now- perfect for cutting Gems..or in my case some of the most translucent Blue Ice (Gem Silica-Morenci,AZ) youse have ever seen light shine thru. My very favorite Gem material, followed closely by Azurite, a soft very difficult material to Cut and Polish..its so dam soft @*##%$*!

Wonder if soaking the Azurite in mixture of Water & Blue Chew pills would stiffen things up ? ; )

Diamond blades are a lot different to carbide or steel blades..Dressing a diamond blade is in a sense, resharpening it. In reality, you can’t sharpen a diamond blade at all but, you are wearing away a layer of flat diamonds that have glazed over. Diamond segments can sometimes glaze over or melt when the diamond blade heats up too much during cutting. This makes the diamond blade appear to be junk, however, underneath the melted segments are a fresh new layer of diamond ready to cut your concrete or asphalt.

Dressing the diamond blade is a simple process. You have to have some material on hand that will wear away the layer of glazed diamonds onto the next. where with carbide teeth you have to sometimes reset pitch..

https://www.sharpeningsupplies.com/products/cleaning-stick-for-diamond-or-cbn-wheels?

https://www.toolocity.com/black-dressing-stone-120-grit-Square.aspx?

The machine I have now will sharpen carbide teeth and steel..blades it doesn’t have a setup like the big unit I had..for hand saws..but I got a bandsaw sharpener for tbose..the hardest thing is in telling the kids don’t rush the blade..let the blade do the work ..if you force the saw late into the wood it will bind up and you’ll get crooked cuts and frustrated as hell..where if you let TBE blade do its job.. it will take longer but your going to have a nicer cut..

https://www.amazon.com/OlogyMart-Professional-Chainsaw-Sharpening-Sharpener/dp/B07HPWWQZR/ref=sr_1_8?

I know that’s for a chainsaw blade..but it will work just as good on a hand saw..its perfect to get the proper pitch and angle..

You bread crusts coming out a little tough there, LOOB?

i wasnt going to mention this openly. i sent it to George privately

because i saw it first hand the day of.

then everyone started saying its fake news, AI generated because Amazon took the book off their site.

then someone really smart used the wayback machine and discovered the truth.

published prior to the event,

https://x.com/hypnolysis/status/1966304594767786225?t=g2uV6JpmJa-OA1O5-ZCdsA&s=19

but but it was just some liberal kid who did it.

hmmmmm.

George, How long does it take for someone to publish a book on Amazon?

From when I hit “Submit,” usually 24-38 hours. I was having a rough time with the “technical problem” line, too.

The author of the book appearing in Andy’s link is “Anastasia J. Casey”.

Anastasia = ‘resurrection’

j = i pre-1524

i[d est?] = ‘that is’

Casey = ‘key’

My browser crashed so my post may be duped.

The name of the book author in Andy’s above link is “Anastasia J. Casey”.

Anastasia = ‘resurrection

j = i pre-1524

i[d est?] = ‘that is’

Casey = ‘key’

So, maybe it was written by the people in the Utah neocommunist trans militia, who used the TikTok thread (deleted right after the shooting) where this was foretold, several days before the TPUSA event at the University…?

This is not the first such socially-negative event to be published on Amazon before it happened. It won’t be the last, as long as Jew-haters turn to Jerusalem for bogeymen and ignore both the facts and Mr. Occam’s dewhiskering tool. Bebe had recently invited Kirk to come to Israel as an honored guest.

As long-time readers know, I have and use the Norton IM313 sharpening system. I don’t use guides.

When I turned piggies into hams & chops, I used two Forschner 6″ flexible boning knives. These two knives had to be able to carve 6000 hams a day — every day. My first seven weeks on the job, I damn’ near cried myself to sleep every night, because the pain in my forearms was so severe. Not cutting whatever the packers were cutting that day was not an option, if I wanted to eat. Therefore, I cut a couple thousand hunks of pork with a dull knife, until I learned how to make a knife not only sharp, but which would stay sharp for a 12 hour shift.

IMO George’s system is excellent. I learned to sharpen in a trial by fire. Few people today have that opportunity, but lotsa folks still need a blade that’ll do a job. FWIW, my EDC is a Buck folder. Nobody likes them because the blade is tempered to Rockwell 63 (the steel is so hard, they’re difficult to sharpen. A lot of “professional sharpeners” will refuse to “sharpen” them.) The Norton India stone does a wonderful job on it — if you know what you’re doing. I’ve got Spyderco, Gerber, and a Ka-Bar but the knives I prefer are Boker (Solingen) and American-made military-issue SOG and Ontario fixed-blade fighting knives, an Ontario machete and Cross axes & wedges. You can shave with everything, except the wedges. Dull blades cause accidents — dull axes are extraordinarily dangerous. They hit & bounce, instead of biting & cutting. When you’re carving deer or bear venison steaks, be sure to wear your chainmail gauntlet. They’re cheap, and save fingers & hands…

I had a Buck knife as a kid. Didn’t see one for years until I found one at the Grainger store counter. Joy! Got my Buck knife again!

What??? More than a few “bucks” I’d betcha!

Not that bad. My Buck fixed-blade was

$55, 40 years ago; it’s $75 now. It is comparable to (or possibly slightly better than) my SOG Seal Team which is now north of $200…

While boatbuilding we used to ‘compete’ to have the best edge on chisels and planes, taking them to the wire that would fold off when you laid them on the Arkansas stone after going through the other grits. I had three fellow builders in the same yard and we all had big patches of arm hair missing from checking the sharpness by dry shaving the arm. And I could peel a single shaving full length on 50′ of my Sitka spruce mast parts, a beautiful thin spiral of vertical grain. And the sound that made walking that 24″ plane down the bench was like sweet music.

Hand tools built the world until less than a century ago, and we humans have forgotten how wonderful these highly evolved helpers are. I still carry around and use a drawknife from my German grandfather that has an amazing blade and it must be more than a hundred years old.

Tools.

Every man makes a different stroke with his tool.

Stiks

George

Long ago when you bought the metal lathe I passed on the wisdom of my gunsmith who is now long gone. He was the smith all the other shops who said they had a gunsmith sent their work to.

We were talking about the collapse of society and he said he had found if you can just make small parts ( like springs, odd screws, and firing pins) you can make a decent living. If you want a prime rib not hamburger living, learn to sharpen tool bits for lathes and mills.

For high precision machining there are folks that will get the Machinist Handbook out and dig down into the descriptions for 6 facet drill bits ,and for all manner of lathe bits and end mills. If an airport is close by the sky is the limit as you well know.

If you put together a decent written shop “Quality Plan” for tracking and documenting work steps, so you can make certified parts, well, you should know the rest

My problem, Big, continues to be what I call my “Eye for the frosting.” I go around my shop, eyeing it all, and sure, I can do a lot. But surrounded by frosting, I don’t (borrowing on the LOOB riff) “make enough big cakes.” So I swim in tools looking for many cakes…

The reason why I thought about the big blades… at the time there was three saw mills each had twenty inch one had a thirty six inch blade.. steel huge heavy..six cabinet shops burning through 10-20 blades a month each they all had blade sharpener but the time… lots of man hours … Hundred teeth on one blade Ten bucks a blade I was earning four dollars an hour at the time..I thought it was an investment.. there was a company here locally that made wood corner trim.. lathe .. they closed because the guy that had the equipment died..his widow said he willed his lathe duplicator to me.. I had it forever along with a legacy mill..big dreams back then..

https://i.pinimg.com/originals/98/3a/9b/983a9bb5ae254702241e11a19644c941.jpg

that’s the exact same legacy mill I had.. along with the turnstyle..

https://legacywoodworking.com/

big dreams I was in my twenties then.. fighting with Satan at the hospital collection department ..there just wasn’t any way I could do it…similar to my childhood dreams of being the next wheel adams..I live in a sportsman area where people hunt often.. dont but that’s that.. with all the training and experience in graphics and plate making.. I had the dream..the guy and his son that shot their first buck proud photo on the landscape in high contrast BW.. did I ever mention I love black and white photography..my mother and the projects she gave whenever you said…I’m bored… got me etching with a diamond pen early in life..then etching glass with photo resist.. plate making film..the thought was giving a timeless photo or entrance window..

https://th.bing.com/th/id/R.16cb25398153667fd86136a477ebc074?rik=cz6rcHiCZgS6Gg&pid=ImgRaw&r=0

you seen the photo of the window I made at twenty that I traded for food lol lol getting ready to make another one I just have to scrape the coins and pickup one piece of glass at a time..A friend that has saved my hide a couple times that owns a company made a comment he liked it and would want one..that was fifty years ago..haven’t soldered glass in years..I do still have the tools or some of them …but the gentleman that let me use his glass shop is gone have to adapt and overcome it..I will use my wife’s patter cutting table to make it then get it framed for him for a Christmas gift…he has the picture of my Window from my youth while I still had dreams now one as an old man in my twilight journey..

When I got sick..the doctors thought I should be in hospice..palative care.. the wife wanted to park in the garage and I couldn’t walk..stuck in a chair not good.. so to pay for medicines I was needing and because the wife was let go to get us both off the health insurance..( that’s a normal thing in business especially if your a peon one of the worthless eaters in society) I sold the mill or had the wife sell it and the lathe duplicator and rail guides.. ( I still have a small lathe for making pens.. I sent one to my dear friend with some of the rarest wood)

https://www.motherearthnews.com/sustainable-living/nature-and-environment/underwater-logging-zmaz98onzraw/

we got the drop off from a table we made for some rich guy..he paid a thousand dollars a board foot for the wood.. we saved the saw dust lol lol and when we fathered it he said oh just toss it..hmmm no lol lol.. I would make pens out of them..

60 years ago my eldest brother held full time jobs as a skilled tradesman and 2nd shift shop manager at a factory in a different industry. He saved his pennies and bought the appropriate setup, then spent a few hours every weekend, sharpening milling and lathe cutters. When I asked why, he told me he made more money sharpening cutters for a few hours every weekend then he made in both his “real jobs,” combined…

Portable sawmill mentioned so I thought I would put out a reminder.

Home cut /milled wood for building construction

In many places ALL wood used in construction of buildings has to be inspected and stamped. This means you have to have a CERTIFIED wood grader stop by and inspect EACH piece of wood and stamp it with his stamp. ON YOUR NICKLE!!

The wood may be Free but the Certified Inspection of EACH board IS NOT!

Lots of people forget this when setting up a portable sawmill for cutting their own boards with their own timber. Check out your local requirements before you actually put a nail into a building your are building with self milled boards. Word is sometimes building inspectors are lenient … other times they can be assholes and order what you just built to be taken down.

No building inspectors in rural areas of Texas, so we tend to build what we want when we want it and from whatever materials suit our fancies. The barn I built 40 years ago might not have passed an inspection, but it’s still standing and doing its job.